Keeping your equipment and machinery ready for the next project is important. You never know when someone asks for a custom part.

Whether it is laser cutting, metal bending, welding or metal rolling, you should always have the machinery prepared.

However, keeping your machine in check can be tricky for some, especially those you use for complex processes like a laser cutting machine or a shearing machine.

I’ll talk about laser cutting machines some other day but today, let’s just stick with the shear.

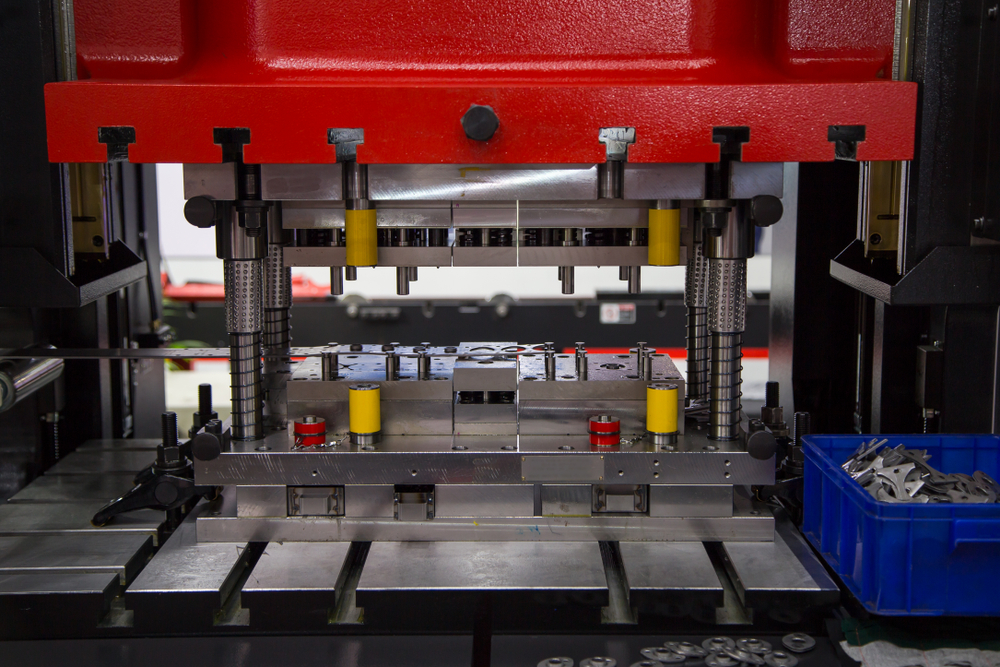

Here are 5 simple ways you can keep your shear in shape.

1. Know your machine

Aluminium fabrication, steel fabrication, and stainless steel fabrication – you know what they have in common?

Among many things, the dependability on machine and automation is what I’m trying to highlight here. Regardless of what metal fabrication process you have in mind, you’ll realize that without the machine, everything is just a theory.

Same goes for the shears. If you don’t know how to use the machine or how it works, everything is just a theory to you. That’s why it is important that you understand the design, function, and operation of the machine. If you know the capabilities and the parameters for cutting with the shear, you won’t overload it and you’ll have a ready-to-work machine at all the time.

2. Regular inspection and review documentation

A regular inspection routine should be followed. The inspection should cover checking the shear’s ability to perform all the operations it was supposed to do, the bearings for wear and slit, and all the safety functions.

After the inspection, it is important that the documents are reviewed well. This assessment of the review can possibly hint to a wear pattern or even a warning to potential accidents. That’s why it is important that the inspection reports are thoroughly checked and dealt with.

3. Setting the blade properly

Setting your shear blade appropriately is critical to stretch the blade and the machine’s life. Setting the best possible clearances for the blade cutting influences the ram, tooling, drive, and cut quality. Also, before setting the blade, the blade seat ought to be checked for ensuring the flatness that is required and to guarantee that the tooling is seated legitimately to dispense with blade chipping caused by moving amid cutting.

4. Leveling the machine

Leveling a shear and also isolating the machine from vibration are musts for proper operation. The correct choice and installation of the isolation pads can increment the tooling life and the shear’s speed, minimize vibration, decrease noise, and reduce distortion of the shear frame.

5. Repair immediately

As soon as you see any wear, tear or damage, it is best to make necessary repairing instantly. Otherwise, the situation can be even worse and your next project can be a disaster.

Conclusion: Even though the use of shear cutting is decreasing over the year, this is still one of the most cost-efficient ways to cut sheet metals. That’s why if you own any, it’ll do no harm to keep the machine in check and prepared for whenever it is needed.