Ergonomics is considered as a nice-thing-to-do in the USA for a long time. But countries in EU, Canada, Australia and few other countries have made ergonomics a law that is a must to abide by. In those countries, the offending business must pay the fine if they do not adhere to the rules, guidelines, and standards. Although Ergonomics in countries like the USA, Singapore, Thailand, India, is still voluntary, nowadays it is not only a nice-thing-to-do. Instead, it has become a must-to-do for metal fabrication industry.

As with most of the business-related decisions, installments of ergonomic machinery and tools come down to the figures and number. Although installing ergonomic equipment costs a lot of money but that doesn’t compare to the cost of accidents and injuries, as well as the compensation for the worker’s medical expenses. Also, the loss of productivity will add to the costs of an accident or injury of your employee.

Apart from saving the expenses that I just mentioned, ergonomic tools and machinery will also increase productivity by reducing wasted movements that consist of lean manufacturing.

Accidents and Injuries Cost Money

MMH or Manual Material Handling injury continues to lead employees’ compensation claims and all their associated expenses according to 2017s Work-place Safety Index, made by the Liberty Mutual Institute for Safety.

The expense of lost-time injury varies, but on average, it is $25000 for each incident. So by preventing one single lost-time injury can definitely save you more than what you would spend on ergonomic equipment.

This particular problem is spreading and it isn’t confined to any single sector. But the industrial workplace report indicates a high amount of MMH lost-time accidents and the employees’ compensation claims, showed by the US Department of Labor.

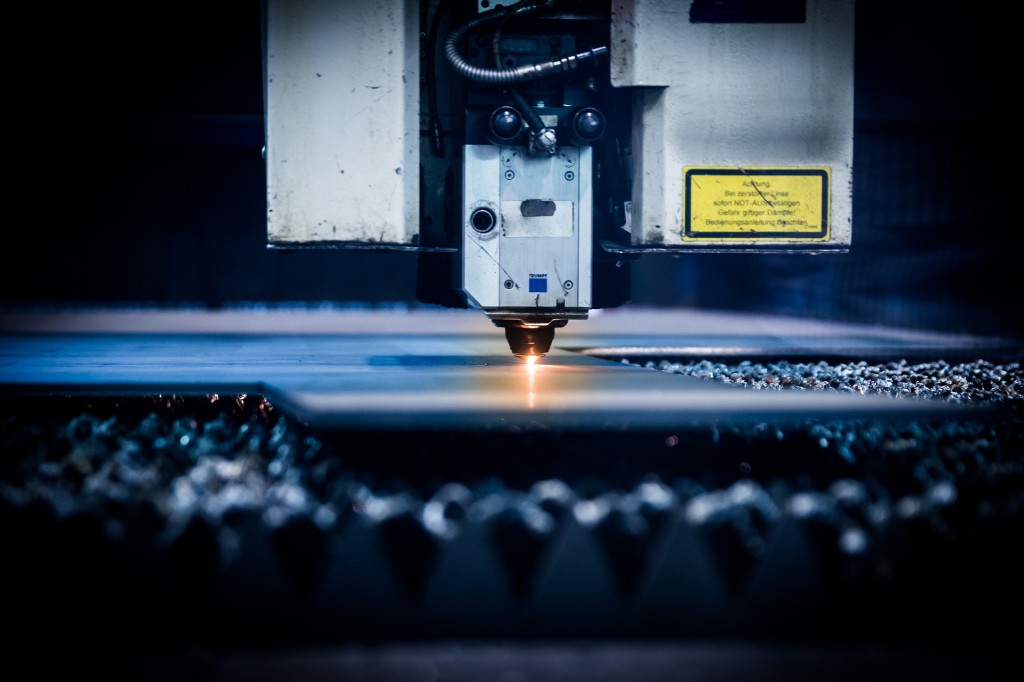

Sometimes these MMH accidents and injuries are incorporated with the poor ergonomics of laser cutting machine, metal bending machine or any other metal fabrication related equipment. The poorly designed workplace and inappropriate manually-handled machines can put your employees at risk. This results in a loss of productivity, lack of quality in production, lost work hours, massive medical cost including compensating claims.

A lot of those claims are results of the accumulated traumas, not any single accident. This includes sprains, tendonitis, strains, and even back pain. This type of injuries usually derives from repeated or excessive stress on the hands, ankles, wrists, elbows, shoulders, and back.

For example, heavy objects should not be lifted from a low angle like the pallet or the floor, bending over in the containers, wire baskets, tubs, etc. should be reduced.

Better Ergonomics Increases Productivity

A well-trained, dependable, productive, creative worker is a standout amongst the most important resources a Metal Fabrication company has. At the point when a worker is missing, notwithstanding for transient damage, the special abilities he or she has created are not supplanted by an alternative. Quality, productivity, and efficiency would all be able to endure. These indirect expenses can without much of a stretch surpass all medicinal expenses.

Often the ergonomics upgrades come in form of a simple upgrade. These could include versatile, easy access machines that help your employees to get rid uncomfortable working positions and reduce bending, lifting, and reaching.

So before the medical expenses and loss of productivity pile up on your annual revenue, it’s time to adopt ergonomic equipment for laser cutting, metal bending, metal rolling, and all other Stainless Steel fabrication, Aluminium fabrication or Steel fabrication related works for the best long-term outcome.