Burned resonator tube, clogged filters, dirty optics, gunk over the gasket and the cutting head – clearly this isn’t the state that you want to see your machine in. Maybe it is the current state of your machine or maybe not. But how would you know?

Well, if your machine is not working as you’d have hoped, get ready to do the cleaning.

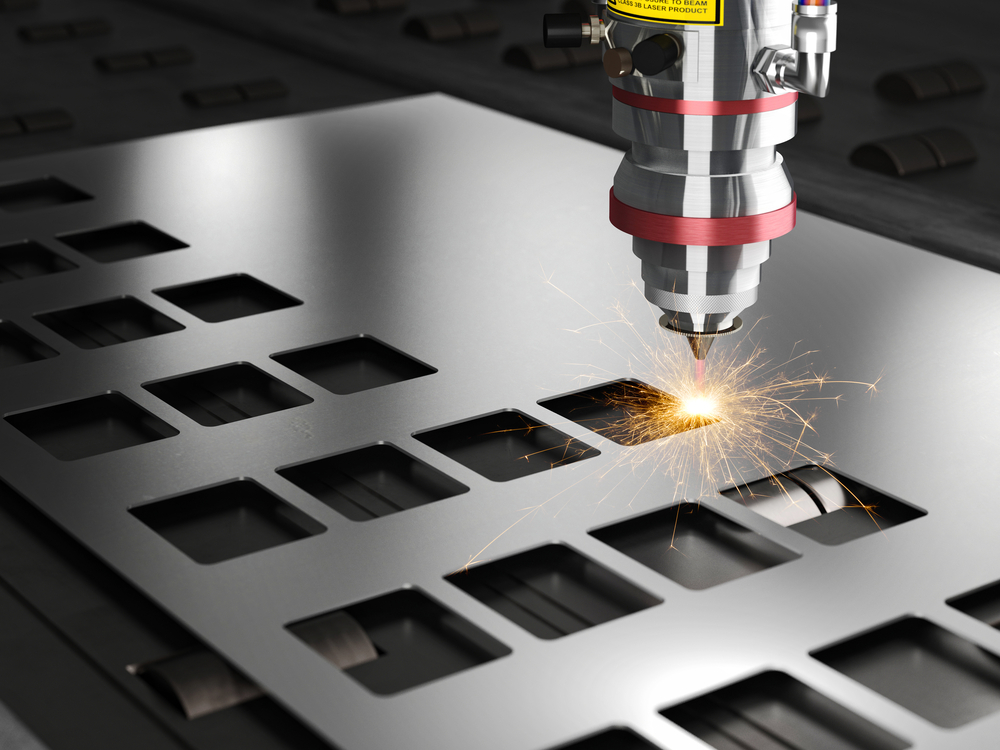

The beam of light and the column of assist gas is the cutting tool for laser machine. But if the machine is not cleaned regularly, the laser cutting tool won’t work that smoothly and the beam won’t pass through the dirt and debris.

When the beam doesn’t pass through the dirt and debris, the laser cutting machines loses its efficiency. And you know that metal fabrication, especially laser cutting is all about precision and efficiency.

For the efficiency of laser cutting, it is really important that the unit is properly cleaned. Otherwise, precision cutting cannot be expected.

Beam Path

Cleaning the beam is easier if your laser cutting operator knows about the lenses and the procedure of changing them time-to-time. Make sure he knows to blow the cutting head’s cavity before he puts it back to the laser cutting unit. For this reason, most of the laser cutting machines have blow nozzle on one side. But if it is not available in your unit, your laser machine operator can look for an unused port and put it on.

Sometimes a regular rubber bulb can do the job for you, although this isn’t the solution. These bulbs have a small flap on their back to draw air into them. But this won’t be of much use if your shop is dirty. You’ll end up only blowing the dirty air of your shop into the lens.

The gaskets in the unit can also be the source of the myriad cutting problems. This introduces dirt and debris into the laser cutting gaskets. When the head of the unit makes contact with the dirty gaskets, dirt is dropped on its newly cleaned cutting lens.

Then the laser cutting machine operator locks its cutting head tightly. The unit then turns the nitrogen purge gas on and this induces the dirt back up into its bellows. This is not ideal if you want optimized laser beams.

Cooling system

Like the beam’s path, machine’s water cooling system also gets dirty very often. It should be cleaned as well. In CO2 laser machine, if the water is not clean, the cathodes be contaminated.

Basic cooling system monitoring includes the water flushing every year. Also changing the chiller filter after every 6 months is recommended by the experts with this unit.

One thing that fabricators fail to realize is if the chiller’s air cooling doesn’t work properly, dirt and debris from the air can enter the laser machine.

The cleaning process is not only important for laser cutting machines. Whether it is stainless steel fabrication, aluminium fabrication or steel fabrication, keeping the units clean after metal bending, metal rolling or any other metal fabrication process saves a lot of your time, effort, and money, in the long run. Eventually, your workshop or units are getting more efficient in their work and this is why we said clean is efficient.