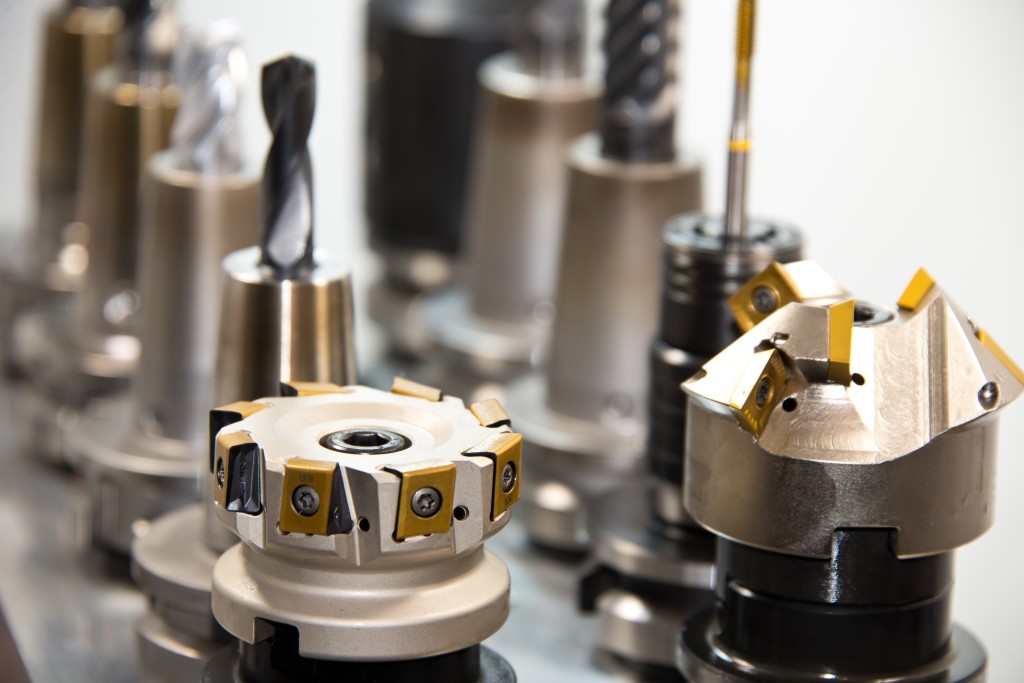

If you didn’t know already, IIoT is elaborately written as Industrial Internet of Things. But what is IIoT and how to use it in the stainless steel fabrication, aluminium fabrication, and steel fabrication industry remains somewhat unknown till this day. However, we can be sure that it’ll be evolving with each failure and success of the early adopters in metal fabrication.

IIoT can turn into a center device in your production and maintenance activities for laser cutting, metal bending, welding, metal rolling, etc. A genuine risk exists that IIoT disappointments can prompt generation disturbance, quality issues, worker injuries, or deaths. Understanding this, IIoT offers some fantastic opportunities. Chances are it will be anticipated from numerous providers sooner rather than later.

IIoT guarantees to:

• Improve repair and maintenance booking for more noteworthy plant dependability.

• Support the production collaboration and administration crosswise over supply chains.

• Support decision takers with present and exact data about production and machine status.

• Autonomously alter hardware to streamline dependability and effectiveness.

With such opportunity, however, there comes risk that you need to manage:

• Network security is basic to forestall malignant disturbance and loss of focused data.

• Successful usage relies upon a high level of dependability and steadiness in current assembling tasks.

• A good amount of skills are required to keep up the honesty of both the data sorting and the production procedure.

• System blunders can prompt employee injuries.

Adopting IIoT

Timing your reception relies upon your present abilities to observe and deal with your generation and upkeep exercises. Right now is an ideal opportunity to complete a “gut check,” strengthen your qualities, and take out your shortcomings. The better you can oversee and gain from your present data, the more prominent your likelihood of accomplishment when arranging multifaceted nature and a tidal wave of information begin coming in your direction.

To get ready for coming changes in your plant information and checking you should ace the accompanying.

• Implementing a prescient upkeep program.

Likely one of the best advantages of IIoT will be its capacity to warn you to conditions that may prompt disappointment. You can fundamentally enhance your plant unwavering quality while lessening your upkeep costs now, most likely with a portion of the instruments you as of now have.

• Monitoring your gadgets and focusing.

You most likely as of now have tonnage screens and other checking gadgets. On the off chance that you explore the manifestations of out-of-ordinary working conditions, you’ll see that vibration, commotion, and oil observing can caution you to potential failures before they happen.

• Learning how to change over information into helpful data.

Transforming crude information into profitable data requires learning of your creation condition, the capacity to characterize a populace, a solid example from that populace, and the capacity to produce and examine the example’s measurements.

• Talking to your store network.

Examine designs and issues with your clients and providers. You’ll see that they have indistinguishable worries from you do. Keeping an open line of correspondence causes you intend to live up to your production network’s desires.