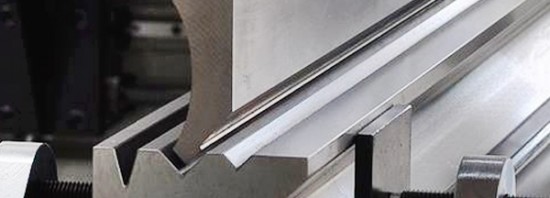

A few days ago, I published an article on the common mistakes in metal bending. Today, I’m thinking of continuing the topic but instead of talking about the common mistakes that we make with all the different kinds of metal bending press brakes, I’m going to dig deep and explain the machine-specific or machine type-specific problems.

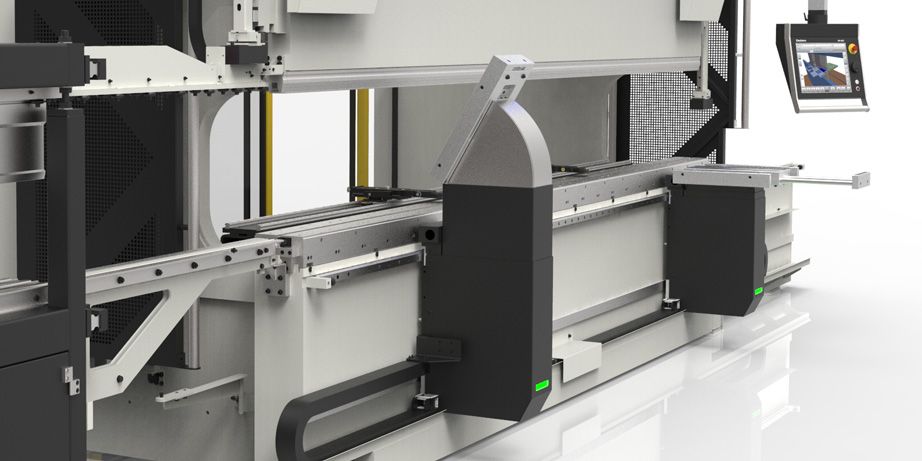

Like any machines or equipment used in metal fabrication industry: laser cutting machines, metal rolling machines, stamping dies, welding equipment, press brake machines also uses different sources of power or functions in different ways.

On the basis of how they function, press brakes come in Hydraulic and Mechanical driven form.

Common Mistakes With Hydraulic Press Brakes

Ram Drifting

Every so often, on 2-cylinder hydraulic brakes, accidentally, the ram starts to drift down on 1 or both ends as the machine is stopped with the raised ram and left completely under pressure with the power turned off. This happens usually because of any internal oil leakage in the cylinder.

The leakage can be repaired by replacing the used internal seal and if the situation is worse, simply place a block under the ram.

Adjusting Ram Tonnage Failure

Hydraulic press brakes can either come with the adjustability of the tonnage function or a fixed one. If by any chance you have one with the adjustability option, take full advantage of it.

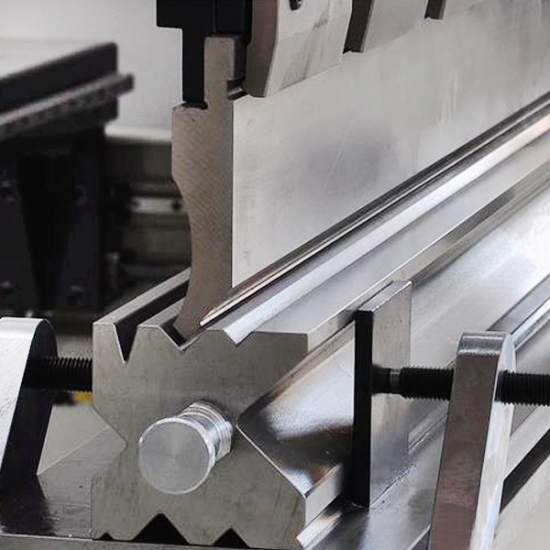

Firstly, make sure the tonnage is minimum. You don’t want to overconcentrate the load then increase the chances of upsetting the ram or breaking a part of the tooling.

However, if you don’t have adjustability function for the tonnage, you should check in with the manufacturer and find out if there are any retrofit units available to the manufacturer.

Not Changing The Hydraulic Oil

This might seem like an insignificant thing to be reminded of but trust me when I say that you are endangering your cylinders, manifold blocks, and valves by not changing the oil.

If the oil is not changed, it can be contaminated with air, water, and debris. This could also lead to machine breakdown in critical temperature.

Mechanical Press Brakes

Excess load

A clear difference between hydraulic press brakes and mechanical press brakes is the latter one can produce a lot of loads that can be described by my excess load. This excessive load can be 3-4 times the suggested tonnage for the machine.

Not Taking Care of the Position Work

Without taking care of the position work, it is not possible to ensure the suggested or rated tonnage for the operation and this could mess up the integrity of the machine. That’s why it is important that you take care of the position work maintain a healthy setup in the workshop.

Conclusion

Avoiding or preventing these problems will benefit the aluminium fabrication, steel fabrication, and stainless steel fabrication process and the metal fabrication shop in general. So, be careful and if possible, organize a training session for your workers & operators and make them more skilled or capable of handling the machine or the problems.