Our Services

Laser Cutting

Laser Cutting Service

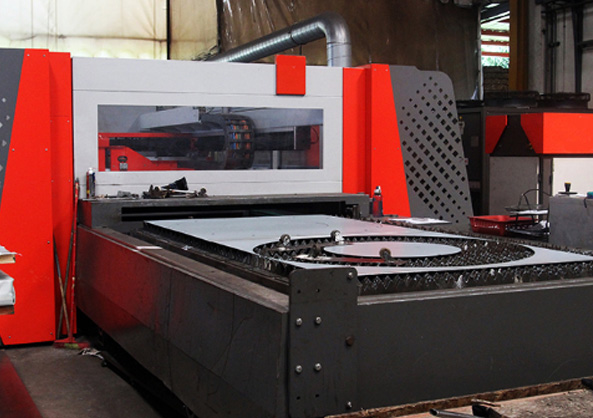

At FMB Trading And Engineering Pte Ltd, we offer laser cutting services using state of the art technology coupled with our efficient, dedicated and well-trained staff; we guarantee excellent services. We deal with a broad spectrum of products including those of mild steel, stainless steel, aluminum, plastic among other metal alloys and materials. We are looking to offer more advanced services on sheet metal and hollow section designed products.

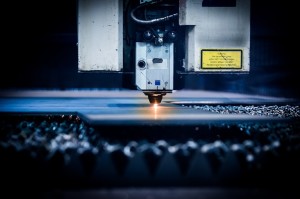

Laser cutting is usually the primary process before metal bending, rolling or metal fabrication of various forms such as stainless steel, mild steel and aluminium. As such, our services are catered to various materials and sizes.

Maximum Material Thickness For Laser Cutting

- Mild Steel : 25mm thick

- Stainless steel : 20mm thick

- Aluminum : 12mm thick

- Copper: 3mm thick

- Brass: 3mm thick

- Acrylic: 10mm thick

- Wood: 30mm thick

We cut a variety of thicknesses. However, the technical data above only specify the maximum thickness that our machines can cut. Call or email us here to find out more how we can help you.

Maximum Material Cutting Size

- 3,015 mm x 1,524 mm

The maximum material size we can cut is up to 3015mm by 1524mm. Any other length and width must be subjected to our fabrication services by joining them up together!

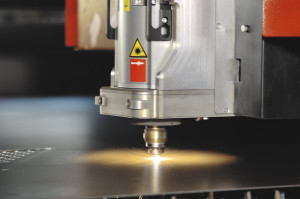

Cutting Tolerance

- +/- 0.1 mm

Our Equipment

- Bystronic ByAutonom 3015 (4.4kw)

- Bystronic BySpeed 3015 (5.2kW)

- Customized Fiber Laser Machine (3.3kW)

Benefits of laser cutting service

Laser cutting method has a variety of benefits. It is a fast and prompt technique that ensures we beat the deadline of orders way beyond the required timeframe with the production of prototypes within a fraction of a time while still ensuring that the products are of high quality and that customer satisfaction is maintained. This is achieved by the ability of the technique to produce components automatically on a single machine, in a single step hence eliminating time spent when various steps have to be employed to achieve similar results.

We also provide the service at much more affordable prices within the market value range in accordance the stipulated market pricing rules. Laser cutting, to a high degree, reduces tooling and jig costs, direct labor and cycle times are also greatly reduced and also energy used hence making it a more cost-effective method ensures that the price of offering this service is more pocket-friendly. Our personnel have also been adequately trained on matters management and maximum use of raw materials during production hence losses associated with wastage of material is greatly reduced making the whole process and overall service production much more cost-effective.

Besides, since we employed the laser cutting technique productivity have greatly increased. Its continuous use has provided mastery of the technique by all our concerned personnel which has led to the production of high-quality products fashioned at maintaining the credibility of our production process and the products at large.

With the use of laser cutting technique, we can produce edge quality products geared towards high-level precision, attractiveness and originality; this is achieved since the method creates room for our personnel and professionals to put into use and practice their creativity and innovation during production. Laser cutting enables one to come up with virtually any shape and design with high precision and accuracy from hollow tubes to open sections such as channels, shapes, and angles.

The expansion of our production and product brands we look forward to better days ahead regarding service provision, higher productivity while still ensuring that we maintain a high quality of products, unbeatable offers an affordable price of our laser cutting service. For more of our capability, visit our capabilities page to learn more.