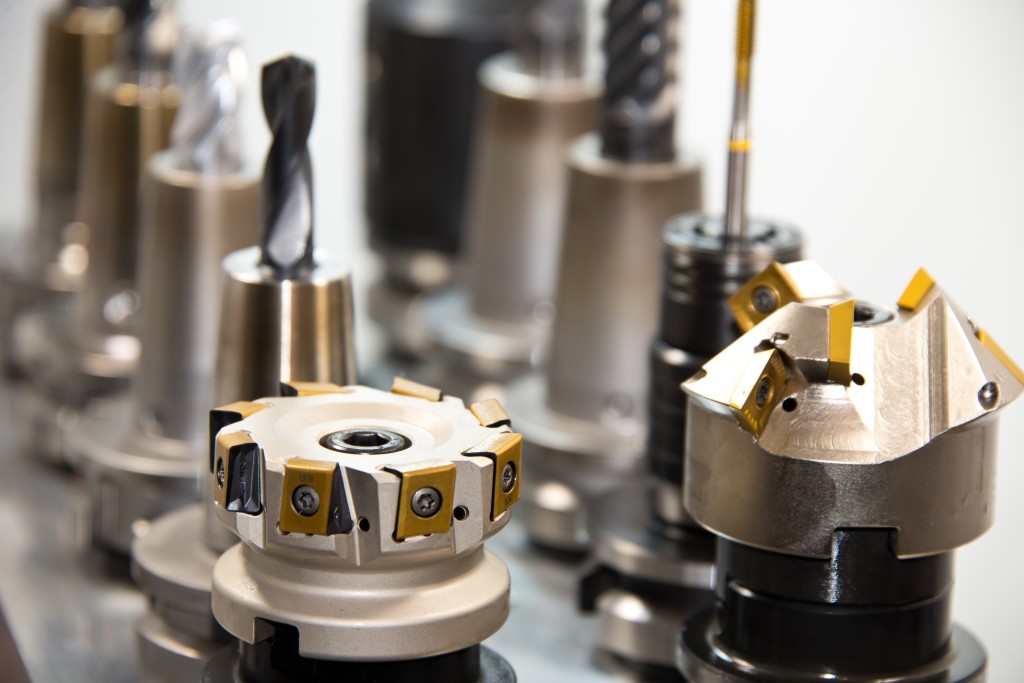

Machine Maintenance is certainly a big part of managing a metal fabrication shop. No matter how good your machine is, if it is not maintained properly, it will start making the fabrication processes like laser cutting, metal bending, welding, metal rolling, etc. inefficient. That’s why to ensure the best results from your valuable machine is crucial for metal fabrication shop owners.

But maintenance for these machine requires labor force. However, sparing a machine operator for the maintenance work only is not a productive decision. This way, you are not utilizing his skills properly. But how about a machine or a program?

Wouldn’t it be great if there’s a machine or program always there in your shop to keep a close eye on the machine?

You know the answer.

Sebastian Christian, the CEO of OtoSense, never thought he would work with forging press owners. But technology doesn’t maintain any boundary. A new technology in one sector will leap into another in no time.

Christian’s AI did that. Although his AI wasn’t meant for metal fabrication industry, it certainly found its place there.

In the year 2015, the entrepreneur won the award for BEST APP at the MWC (Mobile World Congress) at Barcelona. His cloud-connected application was successful in creating an AI or Artificial Intelligence engine. It can mimic very efficiently how a human ear can hear and then interpret the sounds.

This application, at first, listens to the sound around it. For example, it may listen to a knock on the wall, the ringing of a doorbell or even a fire alarm.

But Sebastian didn’t intend to make the AI for industries. He meant it for health care and expected a call from them. But instead, he got the attention of industry tycoons. They approached him saying they have maintenance techs and engineers who rely on the sounds as the prime indicator of “something happening”.

The chief product officer at OtoSense, Jags Kandasamy, said the same. This AI sound-hearing engine is being used for the manufacturing processes and maintenance, especially in CNC Machining, as well as press forging. Jags also expressed his strong gut feeling that the technology will soon be wide-spread in the metal fabrication industry.

This AI tech uses multiple sensors as it is dictated by the application. Pressure sensors, optical sensors, microphone, and accelerometer are few of them. These sensors detect vibration, including the sound waves. Then it sends to the cloud-based Artificial Intelligence engine for interpretation.

The non-contact microphone sensors allow this AI-based technology to be used even in the harshest and sensitive environments. This ensures the use of the advanced AI application in stainless steel fabrication, aluminium fabrication, or steel fabrication.

But as any Artificial Intelligence, this one needs teaching. After all, the thing that makes AI this efficient at work is they can learn from the environment and the input data given by the operator.

People related to metal fabrication industry are feeding the AI system specific data so that the program can use the data and interpret in context.

If the people at metal fabrication industry can work to make it more and more compatible to the machines used in metal fabrication processes, the time is near when fabricators won’t have to rely on the operators to properly maintain their machines.