Metal fabricators always ensure the processes used for stainless steel fabrication, aluminium fabrication or steel fabrication are cost-efficient. Whether it is laser cutting, metal bending, welding or metal rolling, they must comply with the safety code and increase cost-efficiency for the metal fabrication shops.

This is the reason why Spot Welding or Resistance Welding (RW) have a long-lasting run in the metal fabrication industry. However, after so many years, people still don’t realize the potential of RW. It has so much more to offer than just regular sheet metal joins.

Let me tell you about some of the more unusual uses of Spot welding.

Resistance Welding (RW) Annealing

Even though sending the parts through an annealing over can seem like an economical decision, it certainly lead to unwanted distortion. Apart from that, when the production volume is limited, oven annealing is perhaps not the best solution.

A good way is to pass an electric current through its joint. The Resistant Welding control utilizes an integrated infrared temperature feedback device. Then the fiber optic lens measures the temperature which is shown in a lead-in photo. This way, metal fabricators can achieve a controlled temperature rise-&-hold curvature to anneal the joints without forcefully altering the geometry or metallurgy of the part.

Cross-Wire Welding

Most fabricators think RW to be merely a process to join any round wires for making dishwasher racks or store displays. However, this cross wire welding can certainly be used for other components like filaments of light bulbs, bread toasters, to even automotive seating.

Fusing the Stranded Wires

Spot welding or Resistance welding can be used to safely fuse the cut ends or the flat wire cables. Fusing the stranded wire ends could replace the crimp connectors that will increase reliability and reduce production cost.

Dissimilar metals joint using Percussion Welding

Resistance welding is used to join dissimilar metals like components used in the switch gears that are consists of 2 silver contacts which is joined to the solid copper bar.

This Percussion welding takes the help of specialized resistance welding machines that create high-temperature arcs between metal parts. Then it rapidly forges the metal parts together.

Joining the nails

The resistance welding process is often used to join rolls of small to large nails that are used in the pneumatic nail gun magazines. The secret to this process is synchronization between the welding control and nail feed.

Hot Upsetting

This hot upsetting is generally used in the production of different metal parts. Using Resistance or Spot welding process for heating metal rod end before forcing it into the die can help you achieve any shape with maximum precision.

For Hardened Metal

Joining the spring steel and heat treated metal can be challenging. The temperature obtained by RW is usually the same as the temperature in heat treating.

Trying to cool the welding nuggets fast can lead to brittle joints. However, the advanced welding controls let annealing and welding to be done in one-single process.

Keeping your equipment and machinery ready for the next project is important. You never know when someone asks for a custom part.

Whether it is laser cutting, metal bending, welding or metal rolling, you should always have the machinery prepared.

However, keeping your machine in check can be tricky for some, especially those you use for complex processes like a laser cutting machine or a shearing machine.

I’ll talk about laser cutting machines some other day but today, let’s just stick with the shear.

Here are 5 simple ways you can keep your shear in shape.

1. Know your machine

Aluminium fabrication, steel fabrication, and stainless steel fabrication – you know what they have in common?

Among many things, the dependability on machine and automation is what I’m trying to highlight here. Regardless of what metal fabrication process you have in mind, you’ll realize that without the machine, everything is just a theory.

Same goes for the shears. If you don’t know how to use the machine or how it works, everything is just a theory to you. That’s why it is important that you understand the design, function, and operation of the machine. If you know the capabilities and the parameters for cutting with the shear, you won’t overload it and you’ll have a ready-to-work machine at all the time.

2. Regular inspection and review documentation

A regular inspection routine should be followed. The inspection should cover checking the shear’s ability to perform all the operations it was supposed to do, the bearings for wear and slit, and all the safety functions.

After the inspection, it is important that the documents are reviewed well. This assessment of the review can possibly hint to a wear pattern or even a warning to potential accidents. That’s why it is important that the inspection reports are thoroughly checked and dealt with.

3. Setting the blade properly

Setting your shear blade appropriately is critical to stretch the blade and the machine’s life. Setting the best possible clearances for the blade cutting influences the ram, tooling, drive, and cut quality. Also, before setting the blade, the blade seat ought to be checked for ensuring the flatness that is required and to guarantee that the tooling is seated legitimately to dispense with blade chipping caused by moving amid cutting.

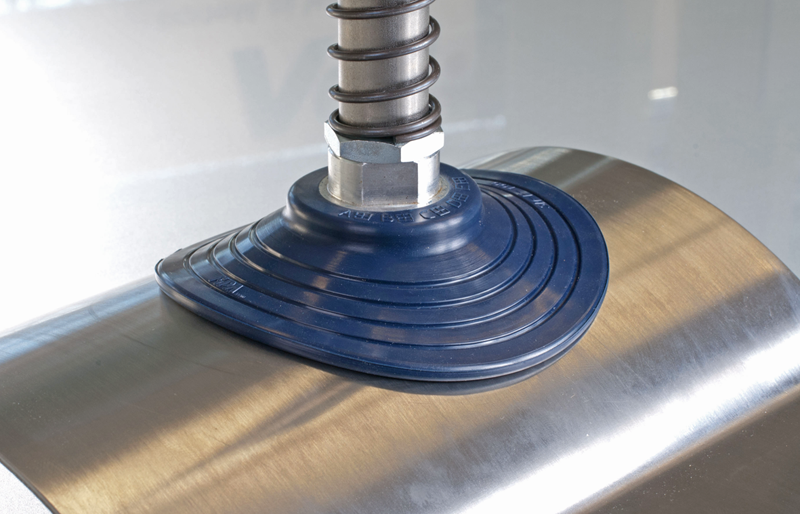

4. Leveling the machine

Leveling a shear and also isolating the machine from vibration are musts for proper operation. The correct choice and installation of the isolation pads can increment the tooling life and the shear’s speed, minimize vibration, decrease noise, and reduce distortion of the shear frame.

5. Repair immediately

As soon as you see any wear, tear or damage, it is best to make necessary repairing instantly. Otherwise, the situation can be even worse and your next project can be a disaster.

Conclusion: Even though the use of shear cutting is decreasing over the year, this is still one of the most cost-efficient ways to cut sheet metals. That’s why if you own any, it’ll do no harm to keep the machine in check and prepared for whenever it is needed.

Hydroforming is quickly becoming the go-to process in the metal fabrication industry, most notably in the automotive sector. They have been experiencing great success in the sense that the process can help reduce weight, overall costs and also the total number of parts per vehicle. There are many factors which affect the hydroforming process and the process comes with several advantages as well as disadvantages, some of the basics of which are introduced below.

The Advantages of Hydroforming

As mentioned earlier, hydroforming has become a widespread and popular technology to be used in the production of structural components in the automotive industry and can often be applied for stainless steel fabrication, aluminium fabrication, and steel fabrication. This is primarily due to the fact that hydroforming allows the engineers to produce designs through cross-sectional reshaping and an expansion of the perimeter. Additionally, hydroforming equips the engineers with the ability to create holes required in the component very cheaply.

Hydroforming also provides some advantages in the case of tubular components, which include:

- The formation of strong and sturdier parts and vastly improved structural integrity.

- Reduction in the weight of the part by designing smarter, more efficient sections and modifications to the thickness of the walls.

- Because fewer parts are produced the cost of tooling is also reduced.

- Less scrap is produced.

Although hydroforming offers its advantages, it does come with a few drawbacks. First off, the equipment for hydroforming processes are very expensive and the process is somewhat slow. Therefore, careful assessment from an economic standpoint for each part is required before diving into it. As for the slow cycle speeds of hydroforming, other smaller processes can be integrated to help cut down on time and make the whole process slightly faster. Finally, it is always recommended to test a component to its limits using computer simulations before it is manufactured via hydroforming.

Tube Hydroforming Process – Factors that Affect It

As the use of hydroforming expands, so do the issues that need to be dealt with in order to properly produce the right parts and the case of the stamping industry, these issues need to be dealt with:

- Preparing the tubes usually involves selecting the material for the tube and its quality.

- Depending on the complexity of the final product, the tube may have to be preformed.

- There are issues with assembling the hydroformed products after welding.

- Selecting a lubricant that does not easily break down at high pressures

Friction and the Lubricant

Friction in the tube hydroforming process is determined by the lubricant, the properties of the material of the tube, notably its surface texture and yield strength and the de surface.

Selecting a proper lubricant for the job requires an understanding of internal pressures, the sliding velocity and the distances involved with that specific part.

Conclusion

Tubular hydroforming is becoming popular due to all the production advantages it brings forth but a careful analysis of how it can be applied to your manufacturing needs is important. Much like other processes in the fabrication industries like laser cutting, metal rolling and metal bending, a lot of factors affect the feasibility of a process and so, knowing beforehand some of the basics behind a process is important.

Laser cutting, metal bending, welding or metal rolling, whatever it may be, you can’t give your best to your clients if you don’t have the best setup and tools.

Skilled operators equipped with advanced machinery is the first pillar of a successful aluminium fabrication, steel fabrication or stainless steel fabrication project.

But choosing the right machinery for your metal fabrication shop can be tricky. They cost a lot and you simply can’t make a mistake, especially with expensive press brakes.

So let me tell you what factors will come to play and help you pick a good press brake for your fabrication shop.

The workpieces

The very first thing you need to consider is the workpieces you’ll be working on. The plan is to buy a short one and a minimum-tonnage machine that will carry out the projects.

Take a look at the material type and the maximum length and thickness you will work with. In the event that the majority of your work is with the 16-gauge carbon steel with a highest 10 feet length, the limit does not need to be anything more than the 50-tons mark for air bending. But if you get a good number of bottoming projects, you should consider the 150-ton ones.

Amount of deflection

You should also consider the deflection prone to happen in a specific machine. Under a fixed load, a ten-foot metal bending press brake has 4-times the deflection in the ram and bed than a five-foot press brake. For the shorter press brakes, usually, less shimming is suggested if you want to get the best works. Besides, less shimming means lesser time needed to set it up.

The radius of the parts

In general air bending, the inner radius 0.1560-times the actual die opening. In air bending, the die opening ought to be 8 times the metal thickness. For instance, while shaping 16-gauge carbon steel, a die opening of an inch is utilized, creating an inside span of around 0.078-inch. To deliver a more firm inside sweep, you have to bottom-bend to create an inner radius almost same as the thickness of the metal itself. In any case, bottom-bending work requires around 4 times more tonnage than the air bending work does.

If you require an inner radius not as much as the metal thickness, utilize the upper punch with your adequate radius at the tip. Then go to the coining strategy for bending.

Accuracy rate

Required angular accuracy has a major role to play here. It is the accuracy of your bends that decides if you have to consider a physically (manual) controlled brake or a CNC brake. If the angular accuracy you are looking for is +/- 1 degree or even less, and can’t compromise with that, you should stick with a CNC machine.

The tooling

Despite the fact that you have a rack brimming with tooling, don’t expect that it is appropriate for the new press brake machine that you are bringing in. Each bit of tooling requires thorough checking for wear and tear.

There is numerous software out there being used in the metal fabrication industry that helps with shop floor control. Whether you run processes like metal bending, metal rolling or laser cutting, having a floor control software that monitors employees and equipment help the general workflow, especially when it comes to big jobs.

Keeping track of progress and repairs

Once the job is accepted, and the CAD drawings and CAM details are created, the project is in a vulnerable state where it can determine what your profit margin will lie. Most shops follow a general rule of thumb for preventive maintenance, after all, ensuring that the shop is always ready to take on the job without the need for repairs and replacements for equipment is ideal practice. The SFC helps a lot with this. Additionally, the SFC keeps track of all costs, equipment and worker details as the job goes along. The software ensures that proper all assigned tasks are completed properly, proper documentation is generated during work, the right equipment is used for the job and they are certified for the job, and finally, the software tracks and makes sure that all parts of the project come together perfectly in the end.

The software can handle unplanned maintenance as well by keeping track of equipment and costs and collect updated reports frequently. This is important because when it comes to big jobs or jobs that need to be completed in a short deadline, knowing details and conditions about your equipment beforehand can help you handle the job better and get it to completion. Keeping track of all this is very helpful during stainless steel fabrication.

Instruction on getting things done

Once the equipment handling and repairing are documented and well taken care of, the next worry is allocating your resources properly, especially the personnel. The software handles this too by providing a set of multimedia work instructions and allocating resources according to the best job flow. Furthermore, it documents the skills and capabilities of the personnel along with the machines and equipment they will be using. So, you will have an updated database of what your shop floor is capable of, what machines you have, and what resources can be allocated.

At the machine level, the software will provide lots of handy information and instructions to your workers that will help the job flow and execution. Additionally, the screen can also show three dimensional CAD drawings and other data. Finally, contact information of people from other departments or special requirements are also displayed so when needed, they can be summoned to the shop floor almost immediately.

Choosing the right software

The biggest factor that determines how useful it will be to you is the amount of data you have and can provide to the software. Moreover, you need to assess the computer expertise of your employees as this will determine how effectively they can use your software. A big job or one with a strict deadline can be handled more easily with a software helping you out, keeping track of all your equipment, personnel and resources and help bring them all together and function as efficiently as possible. The use of the software is not very narrow either, there are applications for it in shop floors that focus on aluminium fabrication or even steel fabrication.

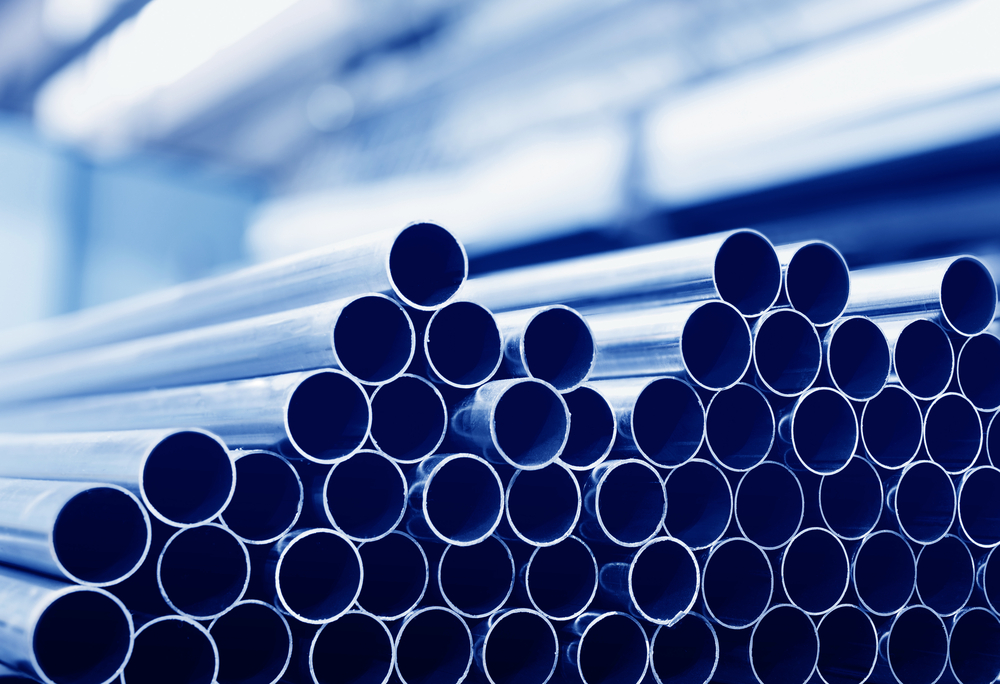

Keeping up with production demands for cut tubing and pipes can be made easier with the help of a band saw. However, maintaining a low cost per cut takes a bit more consideration and effort. Everything from the blade pitch and the workpiece geometry needs to be considered in order to get a proper cut without damaging the blade or the saw. Therefore, blade settings and blade variables need to be adjusted depending on whether you are dealing with stainless steel fabrication, aluminium fabrication or steel fabrication.

Blade Pitch

The blade pitch the number of teeth per inch. This is a very important determinant of both the durability and performance of the blade in cutting tubing. Two forces act on the teeth as they cut through the tubing. They are, the downward force pushing into the tubing and the pulling force as the blade cuts through the tubing.

There are problems with having too many teeth or too little. For example, if the blade pitch is low, there are only a couple of teeth in contact with the tubing. This leads to teeth becoming dull much faster or sometimes, not even penetrating the tubing. In worse cases, the teeth might even be stripped off the blade. On the other end, where we have a very high blade pitch, too many teeth are in contact with the tubing. This leads to the force being so low that the blade will have barely any penetration into the tubing. This makes cutting very slow, and in some cases, leads to work hardening making the tubing almost impossible to cut.

What’s the right pitch?

It is recommended to have 25 in contact with the workpiece at any given time. This ensures that the right amount of force is exerted in order to penetrate through the tubing, and the teeth can withstand the pressure on them.

Multipitch Blades

Some blades come with multipitch specifications. The first number indicates the coarsest pitch and the second number illustrates the finest pitch. Having a multipitch blade is recommended as sometimes, in the case of single pitch blades, as the blade works through a piece of tubing or pipe, the vibrations and rhythm caused by the uniformly spaced teeth may match the natural frequency of the work piece and this might lead to amplification of the minor vibrations which might significantly damage the blade. Therefore, a multipitch blade can help eliminate this possibility.

Blade Metallurgy

This is another important factor in choosing the right blade for sawing through tubing and pipes. The material of the tooth tip determines the abrasive qualities of the blade and how it will function with certain materials. For example, in the case of mild steel tubes and pipes, bimetals blades with a Matrix II 8% cobalt tip is perfect as it provides a good balance of abrasiveness and toughness. In the case of tougher tubing, such as stainless steel, bimetal blades with M42 teeth are recommended as they are very resistant to abrasive materials.

Conclusion

Using the appropriate settings and adjusting blades according to the workpiece is crucial to achieving a low cost per cut. It also prevents your equipment from being damaged. Similar precautions can be applied to other processes in the fabrication industry such as laser cutting, metal bending and, metal rolling to ensure cost-effectiveness.

Simulations play an important role in the metal fabrication industry. They can help you understand and perform a requirement analysis whether you are working laser cutting or metal rolling. This article discusses the use of simulations in metal bending processes.

Simulating Bending

Bending a tube or any other workpiece for that matter results in a multitude of changes to it. Firstly, when a workpiece is bent, the inner region becomes thicker while the outer region becomes thinner. Additionally, there are even possibilities of wrinkles in the workpiece. In some cases, the properties of the material change too due to work hardening. There are some tried and tested methods you can employ to simulate the bending process:

- Modeling the bent tube as a homogeneous tube: This method involves modeling the tube and ignoring all of the changes mentioned above that the tube might go through. This modeling technique is perfect for tubes that are heat treated after bending and tubes that are bent in small angles.

- Modeling the bent tube by only considering any flattening and changes in wall thickness: This required extra work due to extra measurements and data collection. This is especially useful in cases when wrinkles in the structure of the tube are not expected and the tube is heat treated after bending.

- Finite Element Method: This is the method used for studying the behavior of the material.

Behavioral and conditional assumptions

In most FEM process simulations, the deformation of the machine and tools used during the processes are mostly ignored, save for some exceptional cases. However, the reality of it is different. Moreover, the conditions the hydraulic system and the high-pressure systems are often ignored and just assumed that the specified pressures and trajectories will be perfectly applied. However, there have been changes. A significant step forward has been the use of the “fluid cell” option that is now being integrated into various FEM programs. This allows for monitoring changes in pressure as the volume of the part changes and the rate of flow of the liquid changes.

Hydroforming simulation techniques make another assumption. That is, sealing surfaces are always leak proof. However, this is not always true. The part may be uneven sometimes due to plastic deformation. This problem can be dealt with by providing the simulation with displacement boundary conditions to check the respective axial forces.

Simulations, like FEM simulations, help plan ahead when dealing with parts and figuring out the different nuances. However, because the different software is used for the simulation of metal forming process and another for structural analytics and calculations of either single hydroformed parts or a combination of parts. The transfer of data between the two software results in loss and errors.

Conclusion

There are still some areas that need more research and development in the field of hydroforming simulations. There is some work being done with other necessary simulation aspects such as those dealing with the material flow in addition to using the deformation capacity of a particular material used in hydroforming processes. In order to get a full grasp on hydroforming, matching experimental and calculated values is essential in incremental stages of the metal forming process.

The applications of simulations can be extended to almost all parts of the metal fabrication industry, including stainless steel fabrication, aluminium fabrication, and steel fabrication.

Whether it is stainless steel fabrication, aluminium fabrication or steel fabrication, wastes are an ugly truth. No matter what you try to do, laser cutting, metal bending, welding or metal rolling, you’ll always see things lying around here and there and it is really frustrating to get rid of them.

But that doesn’t mean you can simply ignore those. No.

You’ll have to comply with the detailed regulation adopted by your fellow metal fabrication business owners who – like you – thinks about their employees and surroundings.

Identify the waste

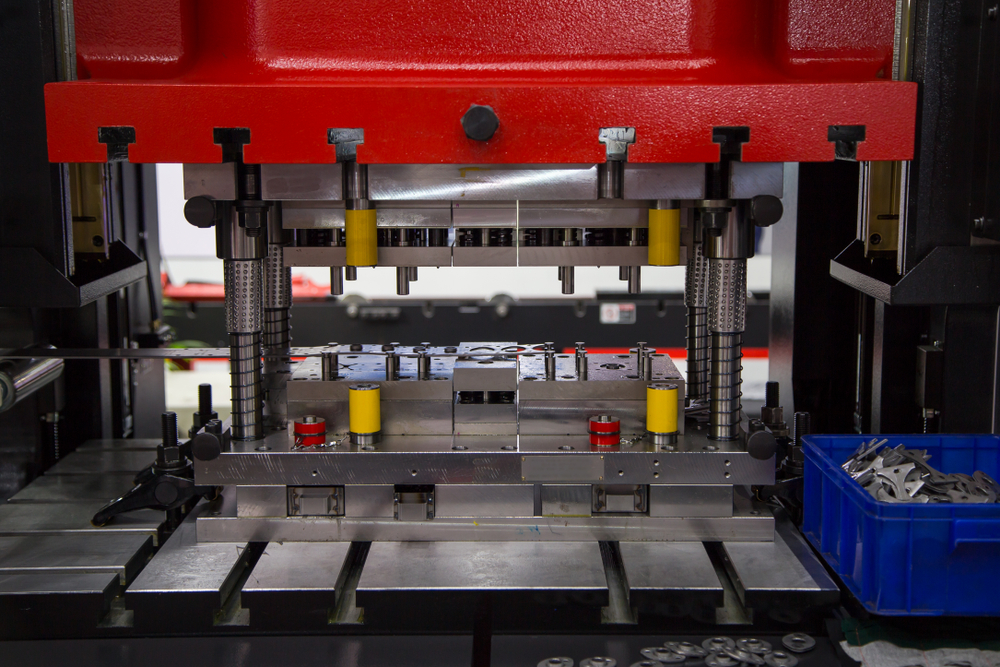

First of all, you’ll need to identify the waste in metal stamping.

In metal stamping, waste simply means the hydraulic fluid, machine oil, lubricants and other absorbent and solutions that are used to clean the parts. But some of the waste may not be as easily identifiable as lubricants.

What’s the quantity?

To develop a compliance program, it is important that you know how much waste your process can produce. Consider the individual quantities of fluid, oil and solid.

Besides, for immediate need, it is best that companies know how much waste they are producing.

Different methods of Waste Treatments

After the pressroom wastes are recognized, current practices surveyed, and the quantity of waste that is created determined, the company must choose which method(s) would be utilized to treat its wastes. It additionally should decide whether its compliance program will be overseen inside or whether it should swing to an outside supplier for help. These essential choices ought to be found on various elements, including the sorts of waste produced and the degree of the company’s on-site resources.

Metal stamping organizations that create nonhazardous wastes either can reuse it into valuable items or, if reusing isn’t good enough for them, recovered energy from the waste can be used in making new items. Waste paint, for instance, can be mixed into a mechanical fuel. Certain kinds of waste, for example, oil, can be dealt with utilizing an assortment of techniques, including re-refining or processing & burning for the energy recovery.

Sorts of utilized oil that can be reused include engine oil, synthetic oil, transmission fluid, compressor oils, refrigeration oil, metalworking fluids & oils, mechanical hydraulic fluid, laminating oils, aluminum and copper wire drawing solutions, modern process oils, electrical protecting oil, and oils utilized as buoyants.

The others kinds of waste can be dealt with and reused continuously on-site. For instance, the quantity of wastewater that a metal stamping organization creates can be decreased drastically using filtration innovation and watery fluid reusing gear. A reusing unit can be utilized on the pressroom floor to regard water-based fluids, for example, mass completing fluids, watery cleaner showers, squeeze water, synthetic coolants, and wipe water. Soils that diminish the helpful existence of the fluids can be sifted and gathered to enhance the cleaning ability of the hardware and the effectiveness of the vibratory media or coolant.

Utilizing the on-site reusing procedures can diminish waste generation by as much as 90%. In addition, the procedure holds and concentrates bigger oil particles and dirt grains in the tank, the unconsumed dynamic fixings in the science can be reused commonly, diminishing substance use by as much as 85%.

Despite being used in high-integrity applications like electronics, medical, automotive and aerospace industries, Plasma Arc Welding or PAW is often overlooked in stainless steel fabrication, aluminium fabrication or steel fabrication as it is much more complex and requires a more expensive set of tools compared to other arc processes. Another reason for the overlooked situation is the fact that PAW is a bit slower compared to other welding processes like Laser beam Welding or LBW.

However, PAW is not the slowest of all. It is faster than Gas Tungsten Arc Welding or GTAW, also known as Tungsten Inert Gas or TIG. Besides, PAW offers a low-cost welding where LBW was your first choice.

Like laser cutting, metal bending, metal rolling, etc., PAW also has its own set of advantages and disadvantages.

PAW is actually a lot slower than LBW. Depending on the laser used in LBW, the speed can reach up to five times of what PAW reaches. However, if you consider the cost of welding, PAW is much more cost-efficient than LBW and few other welding methods.

That’s why in metal fabrication, PAW is still being used as a cost-efficient alternative of expensive LBW where high-integrity and high speed is not a priority.

But PAW has a disadvantage of greater thermal input. This causes wider welds and also some heat-affected zones than EBW and LBW. It causes more distortion as well as losses of mechanical properties.

However, Other than the cost efficiency, PAW has an advantage over them. It is the tolerance to join gaps as well as the misalignments that ensure the use of PAW in Metal Fabrication. Even though the arc is constricted, its plasma column is significantly larger in diameter compared to the beam. That’s why adding fillers is easier with PAW than EBW or LBW.

As for the comparison between GTAW and PAW, PAW has a significant disadvantage which is its complexity. Besides, as you know, the cost efficiency is higher with GTAW.

The narrow arc for PAW is less tolerant to the joint misalignment compared to the Conical Gas Tungsten arc.

However, microplasma’s subtle arc is easily maintained at a lower current level, which gives it a slight advantage over GTAW.

In the 60s, welders were facing challenges in getting a stable Gas Tungsten Arc at below 15 amps. At that time, microplasma was proven capable of overcoming that limitation. Since then, GTAW went through an evolving process.

PAW has a significantly lower limit of current which is almost one-tenth of GTAW. This along with the reliable arc starting makes Plasma Arc Welding suitable for several smaller precision applications including electronics and medical industries.

PAW also offers the advantages of high current over GTAW. That’s why making welds with Plasma Arc welding in the keyhole mode could result in complete-penetration weld in the thicker material in just a single pass.

PAW decreases the needs for expensive joint preparation and expels the needs for any filler material. Also, most material is weld-able with Plasma Arc Welding using the DC Electrode Negative or DCEN. NO wonder PAW is still being used despite being complex and slow.

Getting a wrinkle-free result is not like laser cutting, metal bending, or metal rolling. I know they have their own challenges but compared to them, difficulties of metal fabrication deep draw operations are somehow more irritating.

No matter how hard you try, wrinkles, buckles, oil canning, and loose material is an everyday problem in deep draw operation for stainless steel fabrication, aluminium fabrication or steel fabrication.

Addressing the challenges and getting past them requires extensive knowledge and understanding of the metal flow and how the metal flow is affected by the step beads, draw beads, draw bars and also the effects of part 3D geometry.

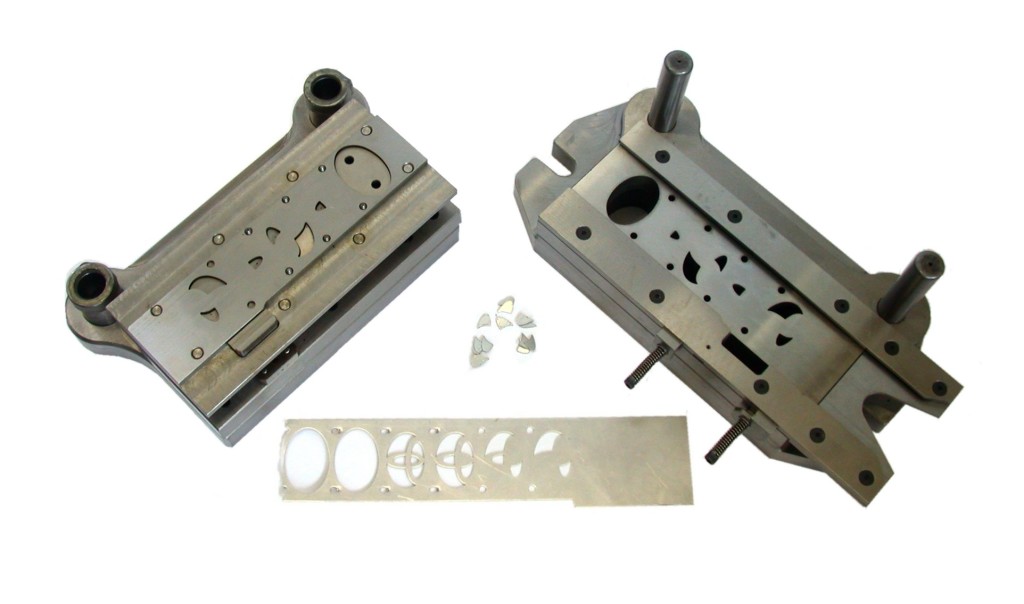

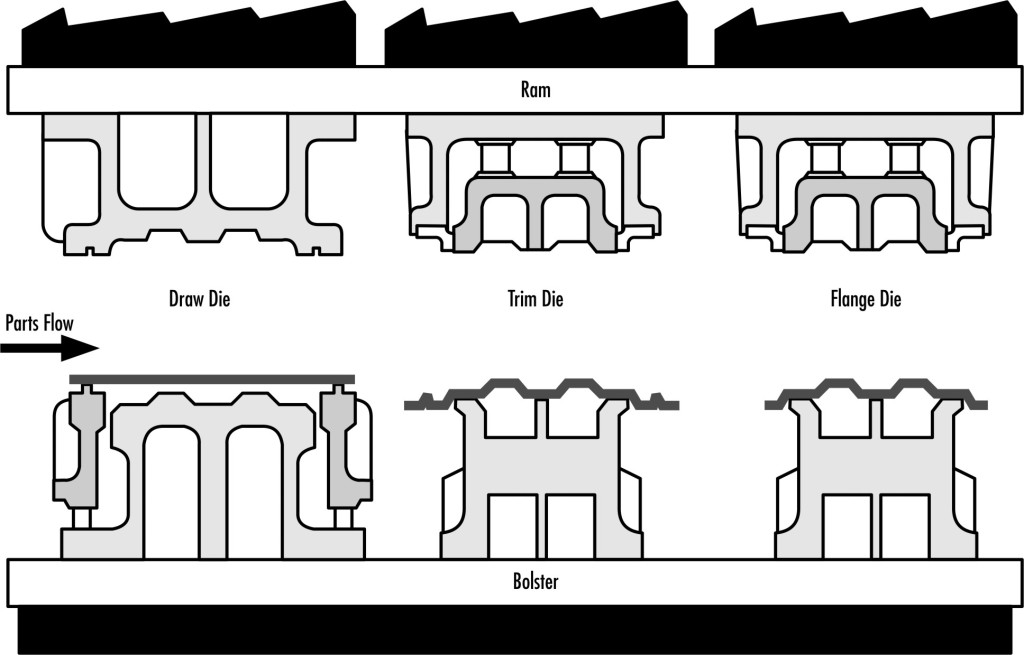

The Draw Beads

These are rib look-alike projections, which are mounted on either the draw ring or the binder. It restricts or controls the metal flow that goes inside the die cavity. Basically, it is a speed bump but for the metal traveling into the die.

Draw beads control the metal pulled into the die cavity with the vertical actions of the stamping press. They force the metal to bend or unbend before going into the die cavity. It creates a restraining force on the material, which causes it to enter into the die cavity at a reduced volume and reduced rate.

The Step Beads

Apart from the shape, the step beads are very similar to traditional half-round draw beads. They are usually located at the outer perimeter and this location allows the bead to have optimal control of the metal flow, which affords the opportunity to save material.

These beads can easily be set with lesser force compared to traditional half-round beads. Also, often these beads reduce strain hardening, which is caused while the bending or unbending process.

The Draw Bars

The draw bars are bumps or just semi-rounded “miniposts”, which are mostly used in Class-A stamping. They are very different from draw beads because unlike draw beads, they are not a part of the die. Instead, they are a part of the draw punch.

They have 3 primary functions. First, they equalize the material consumption for given geometries. Secondly, they hold the blank up off from the post surface. And lastly, they give you the opportunity to obtain stretch presents itself while the bank could be held up off from the post surface.

The Part Geometry

You can understand how much stretching can be achieved during a drawing action just by looking at the shape of your draw punch. In simpler words, when there is a big male radius on the die cavity or on the punch, the material will most likely flow and stretch.

The small radii usually tend to limit or lock off the flowing or stretching of metal. As long as the parts are properly designed, you may expect extensive stretch and flow in both from the binder area and the product itself.

Conclusion: No matter what process you are going through, to get the best result, you must ensure your operators know what exactly goes down there when he turns on the switch. Trust me, it helps.