Sassy Engines is primarily known for producing engines used in the sport of tractor pulling. A bold decision made by the management in early 2017 has put the company into the fabricating world. This step was taken because waiting on smaller fabricated parts for weeks on end caused major delays. And so, considering how they have been doing recently in terms of business, the decision turned out to be a great one.

A brief look at the main issue

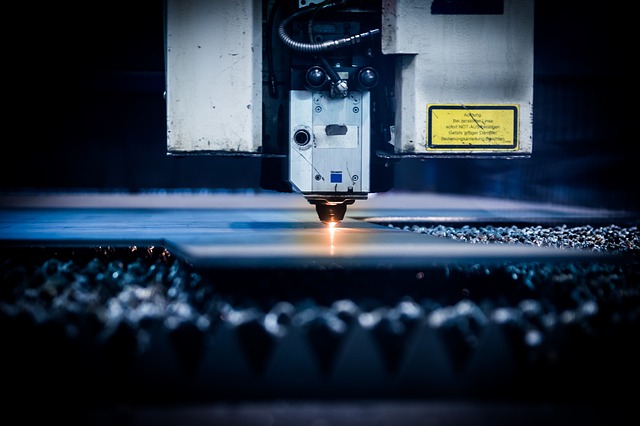

Identifying Sassy Engines as just another engine would be belittling what they actually are. Engines designed by them have made it into over 40 NTPA championships (National Tractor Pullers Association). The company boasts fantastic engines and great experience in the field, as they have been around since 1998. Furthermore, they do not let that expertise go to waste as they use it to great effect when selling parts and making accurate recommendations and combinations to customers. This helped ensure a trustworthy and reliable business. However, they were not without problems. Orders placed on smaller parts to be supplied by other local shops often caused delays. This is unacceptable for a company known for their promptness. And so, at the beginning of 2017, they took matters into their own hands and purchased a plasma cutting table.

Changes brought on by the cutter

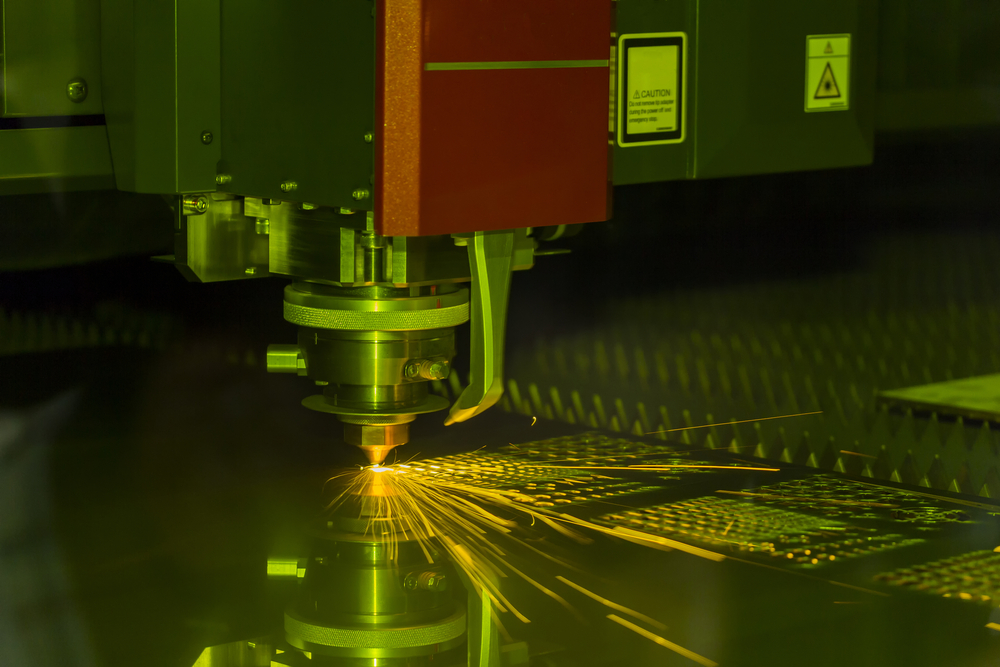

Relying on local shops for custom parts made things difficult for Sassy Engines to the point where it affected project scheduling. And so the purchase of the Swift-Cut pro Plasma 48 table returned some power to the engine-makers. This allows them to internally conduct metal bending, metal rolling and cuts similar to laser cutting for metal fabrication, stainless steel fabrication, aluminium fabrication or even steel fabrication to make parts. Joe Bosworth, the man in charge of operating the machine, faced a huge hurdle. Previously, had had no experience operating machinery this complex and had relied on manual tools for fabricating purposes. However, after some help from the Swift-Cut support team and his own perseverance, he was able to transfer required designs into the PC-controlled machine and produce parts as needed. This has significantly changed things as producing parts now is easier, and much faster. Bosworth had to go through hours of work preparing a design first using wood and then manually work on aluminum, which required over 15 hours of work. But now, he can pump out parts in under 4 hours with the help of the machine.

They are now independent

The shop’s production has never been as efficient. Moreover, they now have the capability to produce parts whenever they need them and produce extras if required by customers. Additionally, they have taken up helping with parts not strictly related to tractor pulling, giving them some business in terms of parts inventory. Finally, after getting more machines like the Hass CNC late and a Fadal 3-axis mill, Sassy Engines has received a massive boost in productivity and are no longer held back due to ordered parts.

In late 2017, Proto Labs Inc., a company with well over two thousand employees dedicated to rapid prototyping purchased a much smaller, RAPID, at around $120 million. RAPID Manufacturing, a company out of Nashua, dedicated to metal fabrication, has been estimated to be worth $8 million around 2010.

Two peas of a pod

RAPID was different from most of its competitors. While other companies concentrated their revenue from a few customers, often times have the top customers make up about 90 percent of their revenue, RAPID has been able to keep things more diverse. They claim that since their inception, a single customer has never exceeded 3 percent of their total revenue. Moreover, even now, their top ten customers only account for a small portion of their revenue.

RAPID’s road to success in this way can be attributed frankly to their practices of rapid response. This is made possible thanks to their eRAPID and RapidQuote quoting software. As a result of this automation, when a customer uploads their CAD file of a required part, they almost instantly get a quote. And so, is very similar to their new parent company, as they share these end goals. The founder of Proto Labs, Larry Lukis, in an effort to drastically reduce the manufacturing time of injection-molded plastic prototype parts, designed a complicated piece of software that instructed a network of mills and presses. Thus, parts could be made in a much shorter time.

RAPID’s growth

RAPID’s growth in the years since its inception has been attributed greatly to the team behind it. Focusing on making the founder’s dream come true and providing excellent and fast service has shoved the company over the theoretical hump a new contender in the fabricating industry must overcome. Their growing sales team of experience folks have helped RAPID thrive and turn into a huge player in the somewhat dominated ecosystem of the fabricator business wherein a majority of the business is through much larger companies. A clean decision to let customer relationship develop over time has helped them thrive and ensure sustainable growth over the years.

The two companies, Proto Labs, and Rapid met each other at various events and slowly got acquainted. Eventually, Proto Labs hired RAPID to get some metal work done for customers. This led to them realizing how similar the two operated in terms of business and sales. Moreover, they could complement each other. While RAPID worked on sheet metal, such as metal bending, metal rolling and steel fabrication, Proto Labs can work on injection molding and laser cutting. Thus, RAPID would handle some of the larger workpieces while Proto Labs dedicated their time to working smaller ones. And finally, RAPID could fill in the void of sheet metal components that Proto Labs lacked. All of this set the stage for a very positive merger and allow the companies to grow even further together. They may even be able to expand their horizons to stainless steel fabrication and aluminium fabrication.

Fails are not a sweet sight for sore eyes, especially in stainless steel fabrication, aluminium fabrication or steel fabrication. Nobody likes their metal rolling machine making uneven rollings or laser cutting machine to leaves bruises on the edge. Same for die fails, no one wants them but only a few knows how to avoid them.

But to put you out of miseries, I’m going to explain to you how you can solve cutting punch fails.

Forming to Failure, metal cutting

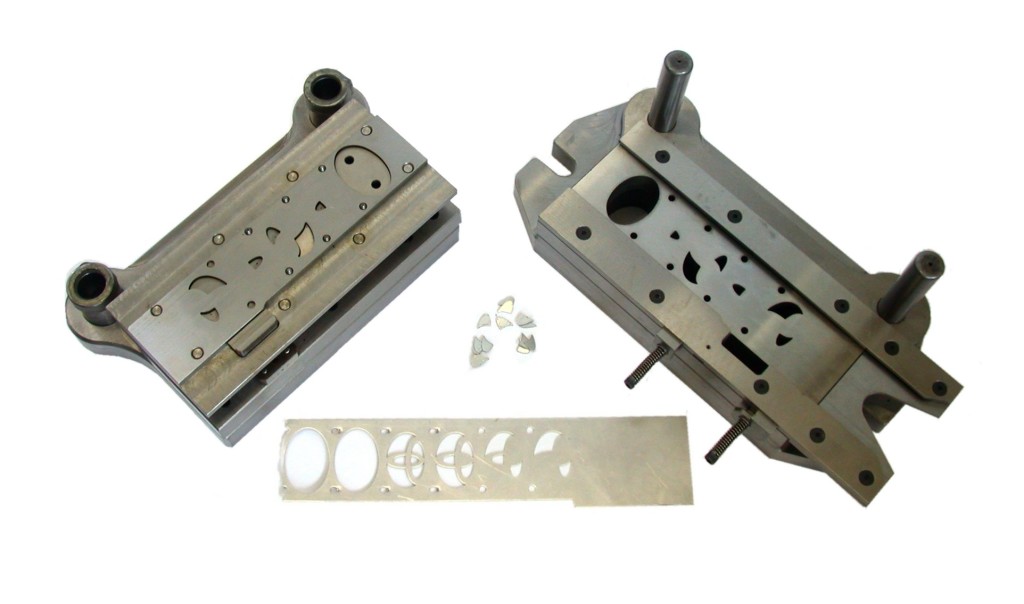

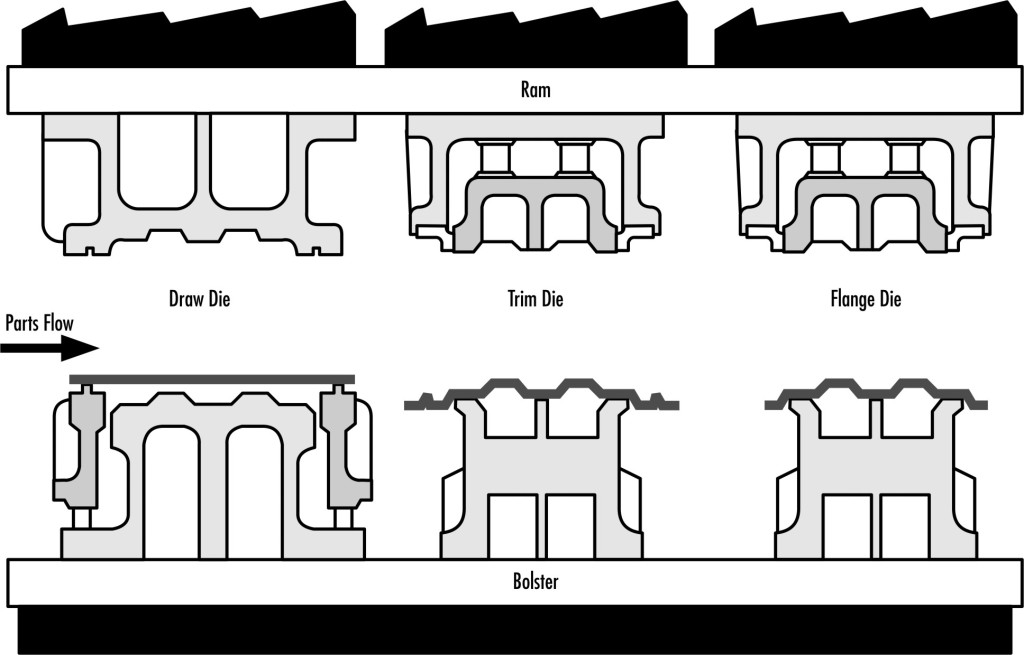

The very first step is to understand die cutting dynamics. Cutting metal in a die is perhaps the most severe metal forming operation. Yes, I said forming operation.

During the cutting process, metal is deformed and the cold extruded from the other part. The deformation produces shear zones or a burning portion of the edge. When the punch penetrates a particular portion, the metal’s some of the internal property like yield strength is exceeded.

Besides, metal cutting requires more force and definitely produces more shock. The shock should be absorbed by a press & the die. Without falling or breaking apart, the press, die, and all its components should absorb the shock for becoming effective in its work. As the tensile and yield strength of metal increase, so do the required force to form the metal to fail, which is called die cutting.

The Press

It is hard to believe but one of the most general causes for a punch breakage is the press. Ensure that the press in your metal fabrication shop is in good condition and well-maintained. It should also have minimal deflection rate when it is under load.

While a gap-frame press (a.k.a C-frame or Open-back presses) works very well for any simple metal bending, low-tonnage cutting, or other light-duty operations.

Usually, they aren’t good enough for the operations, which requires precise punch-to-die alignment and high force. This is because they’ve greater deflection rate than any straight-side press.

Remember, high speed and ultra-precision presses are good candidates for carbide tooling because they are vibration-free and rigid. Besides, they also have lower deflection rate compared to standard presses.

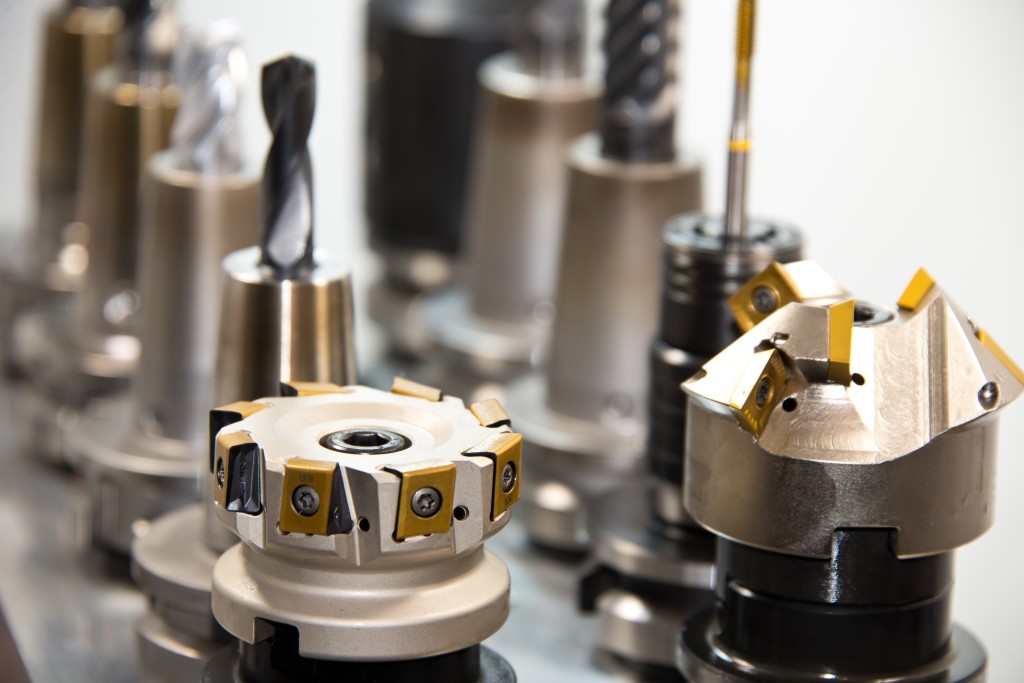

Improper Tool Selection

Cutting and piercing punches should be able to absorb the shocks without chipping and breaking and they also should have a good wear resistance.

Consider the material’s hardness and thickness, clearance cutting, and the ratio of the punch diameter to the material thickness.

As the hole diameter is getting smaller, cutting clearance should start increasing.

Post-EDM Stress Relieving

EDM or Electrical Discharge Machining process can cause the steel damage, which can result in the premature punch breakdowns. From a microscope-level, the wire burns look like bolts of lightning. The discharge creates molten craters of steel lava, which discharges out from the tool steel selection.

Using a lower amperage skin cut, you can reduce the tool steel damages. For an intricate wire-burn punch, the wire-burn section must be stress-relieved after the EDM. The tampering process restores cutting edge’s toughness while keeping necessary hardness.

Robots have been in the custom metal fabrication shops for years. But they are mostly placed there for a specific task like laser cutting, metal bending, metal rolling, and especially welding.

Small fixture designs, workpiece handling, etc. have made this welding robot more flexible to work with. However, if you visit any metal fabrication shop, there’s a high chance you are going to see a welding robot lying idle, while the entire unit is busy.

That’s why many metal fabrication shop owners are forced to find out the untapped potential in the collaborative robots. These collaborative robots or cobots have found their home in many assembly operations and now they are strengthening their foothold in the metal fabrication industry, even in complex stainless steel fabrication, aluminium fabrication, steel fabrication processes like welding.

Collaborating with the people

Ever saw the traditional articulated-arm robots performing some air actions between the welds? If you saw, you’ll know exactly why they need safeguarding.

They move like flying saucer, can hurt someone very badly. That’s why they are not so collaborative with people. But this is not their fault. The machine is just doing what it is programmed to do, nothing else. It’s not like it has some artificial intelligence.

But the collaborative robots or the cobots are smart enough to any obstacles. When it sees and senses any obstacles, it stops. The cobots can sense pressure and that allows it to secure the part, just like a human.

Although it needs some sort of safeguarding, it is nothing compared to what any traditional robot needs. To be honest, these cobots are more like collaborating with people for any work rather than fully doing it automatically, hence the name collaborative robots.

Not just from point A to B

For a cobot, welding is somewhat different than any simple assembly task. Still, the cobots are being more and more integrated.

This system is well developed to be tooled up for different tasks like metal bending with a press brake, notching on to the notching station, punching on to the punching station, etc.

Some metal fabricators even used these collaborating robots for running smaller parts on the press brake. In such cases, the robots can sense whenever a blank has hit the back-gauge. After that, it actuates its bend cycle and reorients the parts.

In most of the applications, beginning and end point of the robot’s path matters. But the path for these collaborative robots doesn’t matter that much. In such cases, these cobots just calculate the best and most efficient path between those two points.

But for welding, the start and end point matters and the path too. This is because of obvious reasons, the welding. However, the welding program that comes with these cobots is equipped with basic welding parameters such as arc starting at the beginning and as well as the crater-filling & shielding gases post-flow in the end.

The program also includes controlled burn-back that applies welding parameter to allow wires to burn-back slightly inside the guns, ensuring the wires don’t get stuck.

Ever heard a metal fabrication shop manager talk about career path management? It almost never happens.

Some would say they don’t have time for that. They would think they just need to keep working. That’s why some of them can’t push their luck to the edge. But if they knew the steps towards a successful career path management in metal fabrication, their companies would have been on the better side of the equation.

Lucky you. I got the magic mantra to a successful career in metal fabrication.

Step One: Management training should start from the top

Bad management leads to bad processes like bad metal bending parts, uneven laser cutting products, unprofessional steel fabrication, etc.

“How,” you ask?

The math is simple. A not-so-good supervisor or manager will never know the difference between a good employee and an unprofessional one. Mainly because he is not trained to do this or he just inherits the place from their ancestors and didn’t have to build it from scratch. Either way, his career in metal fabrication won’t be a good start and it won’t end with awards too.

Besides, if a good employee sees that his boss is not well trained to appreciate his work, he’ll leave anyway.

Step Two: Setting up a clear performance expectations

It’s hard to discuss employee career plan unless you have a proper assessment of their current performance.

If the supervisor doesn’t know how his metal rolling operator is performing, how would he know what to expect? It’s not only about metal rolling, it’s true for welding, metal bending or any other stainless steel fabrication and aluminium fabrication processes.

So, assessing your annual and monthly performing will be your next step to predict your future performance.

Step Three: Know different paths

If you ask a well-performing press brake operator if he would like to become the manager, he’ll nod his head without any doubt.

But if you personally ask him why he wants to be the manager, he’ll say for the higher pay grade. It’s not his fault. Everyone likes to get paid higher. But if the operator becomes the manager without any training, what’ll happen to the company. That’s why a metal fabricator should think other ways to pay their employee better. They should be paid higher only because he is becoming the new manager or supervisor. The pay grade increase should also not be based on seniority. It should only be on the performance basis.

Step Four: Be practical and honest

Employees are bound to leave the company if they are not paid well or they are not appreciated enough. When they see a better opportunity to grow, they will flee.

But a small company may not be able to convince him to stay. Some might not have the opportunity to give him that he deserves. But you should give him false hope. Be honest and practical. If you are a good boss, he might listen to you and stay there for a while.

That’s why metal fabricators need to be honest and practical about the future. If they are not, the company that he built from scratch, might not survive that long because unhappy employees result in unsatisfied clients.

Leo Valerio, a veteran metal fabricator who has work experience of more than forty years in his metal fabrication shop, the Valco Planer Works Inc. that joined after his father had set it up with the top-notch machines of that time. It was 1986 and he has been around those machines ever since.

Of course, there had been changes to the laser cutting machines, metal bending press brakes, welding equipment, metal rolling equipment, etc. Some even got replaced entirely by their advanced, automated, and modern counterparts.

The metal fabrication company also changed its name along the way. Now you’ll find it as Valco Precision Works.

They have machinery for sandblasting, industrial finishing, fabricating, and of course, welding. So it’s safe to say that he has seen a lot of machines in his 40 years of experience.

This means he has seen the machines develop as new and automatic parts take over. The initial designs for many machines changed dramatically. But he can’t say that he has seen any drastic change to the traditional seam welding equipment.

After being charged with the building seam welders for a client, Valerio thought that he can do much better with the designs for traditional seam welding machines. He and his entire team put their thoughts and efforts to the limit and debuted their modern take on the seam welders at 2017s FabTech, the trade show at Chicago later that year.

These seam welding machines are being sold by another company called MITUSA Inc. Their name stands for “Made in the USA”. These MITUSA units are designed to help you achieve higher accuracy.

Generally, the traditional seam welding units track setups with the cam followers to move where the seam is being made on the metal pipe or tube. But these newly designed seam welders use linear rails that have bearing blocks. This gives the fabricators a great hold and free travel with the carriage. This way, the fabricators can put a lot more weight on them without having to worry about the carriage tottering or teetering.

This additional hold-strength gives the fabricators a higher rate of accuracy. Also, it lets the welding power source to be mounted on the wall.

The tracks are machined to a .005 inches straightness tolerance. This way, the seam can be straighter than it would be with a traditional one.

Once MITUSA was able to improvise the mechanical aspect, it was time to look for the best operation controls. They figured that the control needs to be rugged and also flexible enough to meet their customers’ applications. After a while, MITUSA found all these characteristics into the controls from Computer Weld Technology.

This company is well equipped to control any to all arc welding process and also has suitable memories to store different weld programs. Besides, it is very easy-to-use and the interface is smooth.

Overall, if the modern design gets the attention that it deserves, the changes will be clearly visible to the stainless steel fabrication, aluminium fabrication, and steel fabrication processes. And judging by the appreciation that modern and automated technology got in metal fabrication industry, it’s safe to say that not only this new take on welding but also everything that can help metal fabricators to achieve higher precision will get the attention it deserves. Besides, more and more reinventions in the design are becoming a demand for this industry.

Leo also believes that once their modern take is spread throughout the world, more and more fabricators will be interested to develop the existing models of machines to get even better products. Better results will in terms, result in greater company reputation and honestly, who doesn’t want that?

If we are being honest, metal bending press brakes are one of the most dangerous machines that metal fabrication industry is blessed with. According to The US Department of Labor, these press brakes causes more than 350 amputations each year. But these are only the reported ones.

This explains such strict words from labor safety-related organizations towards the metal fabrication shop owners.

But why Press Brakes are Dangerous?

Regardless of the age, your press brake can cause serious accidents. The main danger is in accessing the point of operation. Also reaching around its safety device to get exactly to the operation point at the machine’s end.

The quick backgauges and the pinch point pose great risks to the press brake operator too. It doesn’t stop here. Metal fabricators often get refurbished or used press brakes to save from the machine expenses. Most of the time, these press brakes conditions are not entirely safe. First of all, their primary controls can be faulty or the parts may be too old to work as planned. These faults always possess a great threat to the machine’s operator.

Basic Options for Press Brake Protection

There are several options available for the safety of a metal bending press brake.

The primary type of safeguarding the press brake is a fixed & interlocked barriers that are coupled with a two-hand control. This isn’t a functional approach as the work-piece is always held close to the operational point during its braking process.

Restraints and Pull-backs are other approaches towards physical protection. But both of them have limitation and restrictions. That’s why they are not popular among metal fabricators. They both shackle the machine operator with the press brake and restrict the mobility.

That’s why, be it stainless steel fabrication, aluminium fabrication or steel fabrication, operators try other approaches. There are some more functional approaches that are far better than the previous two.

Two hands down or foot-through the device is a great approach for metal rolling or metal bending machine operators. In this method, operators need to place their palm on the pads and their foot pedal needs to be engaged long before the ram can come down.

In some events, this will work. But this one raises ergonomic issues. Besides, this method is much slower and given by the nature of metal fabricators, it’s safe to assume that this one is not metal fabrication shop owner’s favorite.

Electrosensitive Protection

This one is a new adaption to the safeguarding of these machines. This is Available to the fabricators centered around the electrosensitive protection devices. The light curtains are one of the most important and popular safety tools for this category.

It started as the simple device that can detect product but it evolved into a full-on machine guarding product.

Laser Focus on the Safety

AOPD is the newest addition to the press brake safety category. It gives the machine operators a close proximity to the operation point.

The biggest advantage of the AOPDs is that the operators can easily handle their workpieces up close to the dies during the time when they are using machine’s foot-switch to active machine cycle.

Conclusion: To avoid any causalities in your workplace, safeguarding your press brake isn’t enough. You need to adopt safety measure to the laser cutting machine, metal rolling machine, welding equipment or any other metal fabrication related tools that may possess a potential threat to the machine operators. Only then, you can say with confidence that your workers are safe with the machine and the overall structure of the facility, thanks to the safety measure you took.

Machine Maintenance is certainly a big part of managing a metal fabrication shop. No matter how good your machine is, if it is not maintained properly, it will start making the fabrication processes like laser cutting, metal bending, welding, metal rolling, etc. inefficient. That’s why to ensure the best results from your valuable machine is crucial for metal fabrication shop owners.

But maintenance for these machine requires labor force. However, sparing a machine operator for the maintenance work only is not a productive decision. This way, you are not utilizing his skills properly. But how about a machine or a program?

Wouldn’t it be great if there’s a machine or program always there in your shop to keep a close eye on the machine?

You know the answer.

Sebastian Christian, the CEO of OtoSense, never thought he would work with forging press owners. But technology doesn’t maintain any boundary. A new technology in one sector will leap into another in no time.

Christian’s AI did that. Although his AI wasn’t meant for metal fabrication industry, it certainly found its place there.

In the year 2015, the entrepreneur won the award for BEST APP at the MWC (Mobile World Congress) at Barcelona. His cloud-connected application was successful in creating an AI or Artificial Intelligence engine. It can mimic very efficiently how a human ear can hear and then interpret the sounds.

This application, at first, listens to the sound around it. For example, it may listen to a knock on the wall, the ringing of a doorbell or even a fire alarm.

But Sebastian didn’t intend to make the AI for industries. He meant it for health care and expected a call from them. But instead, he got the attention of industry tycoons. They approached him saying they have maintenance techs and engineers who rely on the sounds as the prime indicator of “something happening”.

The chief product officer at OtoSense, Jags Kandasamy, said the same. This AI sound-hearing engine is being used for the manufacturing processes and maintenance, especially in CNC Machining, as well as press forging. Jags also expressed his strong gut feeling that the technology will soon be wide-spread in the metal fabrication industry.

This AI tech uses multiple sensors as it is dictated by the application. Pressure sensors, optical sensors, microphone, and accelerometer are few of them. These sensors detect vibration, including the sound waves. Then it sends to the cloud-based Artificial Intelligence engine for interpretation.

The non-contact microphone sensors allow this AI-based technology to be used even in the harshest and sensitive environments. This ensures the use of the advanced AI application in stainless steel fabrication, aluminium fabrication, or steel fabrication.

But as any Artificial Intelligence, this one needs teaching. After all, the thing that makes AI this efficient at work is they can learn from the environment and the input data given by the operator.

People related to metal fabrication industry are feeding the AI system specific data so that the program can use the data and interpret in context.

If the people at metal fabrication industry can work to make it more and more compatible to the machines used in metal fabrication processes, the time is near when fabricators won’t have to rely on the operators to properly maintain their machines.

Who doesn’t want a precision plasma cutting? It’s shiny, glossy, and it works exactly how you want it to. You get minimal edge rounding & washout with the precision plasma cutting.

Since the development, mechanized precision plasma cutting made a long way. Although the approaches were different depending on the system, technology that led to the advancement of plasma cutting has similar ingredients: a shielding gas, a plasma gas, and the guide that allows to create just the right energy and pressure levels to cut precisely.

Cutting Challenges

Traditional Plasma cutting machines tend to leave a rounded-top edge and the edges aren’t perfectly squared, unlike laser cutting machines. These edges also pronounced lag striations while the torch “pulling” its arc along.

This lag usually causes challenges for the sharp corners, especially in materials re thicker than 0.5 inches. When the top of its arc makes a precise turn, that lagging bottom of the arcs is pulled around, resulting in rounded corners. But unlike metal bending, welding or metal rolling, the slightest mismatch in the edge may not give you’re the product you are supposed to deliver.

That’s why metal fabricators developed cutting programs that tell the torch to slow itself before it can reach to the corners. You can’t compromise with the precision for any metal fabrication process of any sort. So the metal fabricators had to develop these programs.

There is another challenge with such interior features such as, slots, holes, etc. that involve dealing with a lead-in & lead-out of the cut. For avoiding even the slightest amount of extra material on the corner, the technicians program their plasma cutting machine to cut a little beyond the starting point. This leaves a tiny area that’s essentially cut twice, washing out a little more material which is compared to the rest of the kerf.

Gas Flow Ballet

The precision plasma cutting technology has changed these challenges through gas flow ballet, for better of course. After the precision cutting is introduced, the challenges are minimized through something you can call a swirling gas flow ballet along with electrical resistance as the music.

The Main Players: Hydrogen, Nitrogen, Oxygen & Air

The VP of an ESAB Company, Global Plasma Automation for Thermal Dynamics, Mr. Dirk Ott stated that they have perfected the gas flow and pressure over the recent few years and added that there are multiple approaches to mix out the gases, whether it is shield gas or plasma gas for improved surface finish. This is great news for metal fabricators. But they should also remember that the values are constant for all fabrication projects.

For instance, in stainless steel fabrication, plasma gas usually works well for material with 0.375 inches of thickness or less. But for thicker material, there are different mixtures of gas like F5, H35, etc.

Similarly, for aluminium fabrication, things are not the same for all material. Nitrogen with plasma gas along with water gives an optimal cut and the conditions are different for steel fabrication too.

But only the right gas won’t do the trick. Fabricators need to bring the perfect gas mixture, automation program, and steady operators to get the cut they need and deserve. Otherwise, the motive of precision plasma cutting won’t be successful.

In every metal fabricator’s book, material is the most significant item for every and any metal fabrication process they offer. In 2017’s Financial Ratios and Operational Benchmarking Survey by FMA (Fabricators and Manufacturers Association Intl.), it is shown that the average of direct raw material purchase costs from the responders was 34% of total sales. This is more than the total labor cost, indirect or direct.

Some would say their fabrication process requires more labor power than others but still the material cost is far and large than the labor cost.

Whether it is laser cutting, metal rolling, TIG/MIG welding, metal bending, or just plasma cutting, material is the main item for the entire fabrication process. But scrimping on the material quality has its own costs. Managers and fabricators should know to distinguish between good quality and good coil processing for getting the best deal.

Stretching, Stress, and Compression

The processes that are used to produce sheet metals at the factory result in sheets with trapped stresses. Actually, the metal sheets are the product of balanced compression and tension.

The metal sheet becomes flat when these forces are at the equilibrium, which is the internal stresses in the sheet canceling each other. But the stresses are still there. These stresses are tugging on the ropes and when the laser cuts the material, some ropes that are holding the equilibrium snaps. This causes the workpiece to bow. That’s how you get your sheet metals to bend the way you want it to bend.

See, once the structure and formation of sheet metal is in your head, the concept of metal bending has become much easier.

Similarly, if you know the material you are buying, there’s a high chance you’ll get the fabrication process right. And what’s better than impressing your clients with precise products.

Know your material’s ins and outs

Besides knowing how the raw material for you stainless steel fabrication, aluminium fabrication, or steel fabrication came to you in this form, you should also know the physical properties.

To be honest, there are way too many properties of a sheet metal. But you don’t need to know about them all. You just need few common terms. For example, know the density of the material, evaluate the tensile strength, yield point, etc. for properly judging the quality of your material.

Don’t forget the chemical compound

Most fabricators don’t pay attention to the chemical compound or the ration of the elements used to produce the sheet metal in their hand. This is unwise. They do not know how significant the chemical compound and the molecular structure is for metal fabrication processes, especially for welding.

Also, the ratio of elements in your sheet metal tells you a lot about how the sheet is going to behave when put under pressure. You can assume the overall behavior of your material if you can access the chemical ratios and quantitates.

Conclusion: While most fabricators forget this stuff, there are some smart ones who will never buy any sheet material without checking then density. Yes, they exist. And they are the ones who are dominating this metal fabrication industry.