High-powered and efficient fiber laser cutting machine, High-precision press brake machine for metal bending, Super-fast welding robots, and robotic metal rolling machines comes to mind when we hear cutting-edge technology in metal fabrication.

Power tools aren’t granted as technology these days. They are left in the storeroom or toolroom. But fabricators might be missing some real potential for the shop floor efficiency if they continue to treat the power tools this way.

If you think about how much the platform for power tools changed over the last few years, you will understand the depth.

Thanks to the shifts from Alternate Current to Direct Current power sources, many fabricators are now working with cordless power tools. This efficient transition was led by the advancement in battery technology, such as evolving to long life lithium-ion platform from the traditional nickel-cadmium batteries.

As the cordless tools have moved to the brushless motor technology, metal fabricators and trades-people got more and more power in the hands.

But it wasn’t long that power tools manufacturer realized an astonishing fact about their electronically controlled and motorized equipment.

They asked themselves if the power tools are electrically controlled and motorized then why not add intelligence to the power tool itself and communicate with it. They realized the potential benefit of adding intelligence to their product line. It will start a new revolution in the power tools line up as well as make them more productive than the traditional ones.

This realization led many power tools manufacturer to take necessary steps to develop such power tools that not only make your money worthwhile but also keep your work going at a faster pace, leading to maximum productivity. Among such manufacturers, Milwaukee Tool is one pioneer. In the year 2015, Milwaukee Tool debuted their digital platform called ONE-KEY.

Honestly, the name justifies what it does. It is basically a platform where users can interact with their power tools and manage them. This is one platform for all your tools, as explained by Steve Matson, the senior product manager at Milwaukee Tool.

The initial inspiration and push for this ONE-KEY was centered around its configuration capabilities and inventory management. A user just needs to download the software in his/her smartphone, tablet, or PC to communicate and manage all the ONE-KEY enabled power tools.

Besides, managing the tools, a user can also check the tool’s purchasing information, maintenance schedule, performance history, etc. From the configuration standpoint, a user can easily adjust the parameters of the tool, like the run-time, power, etc. This allows him/her to optimize consumable usage and also to ensure the consistency in setting for similar repetitive jobs.

All these actions can help create a digital home environment for the tools and this is important because the latest era of cordless power tools was most likely to go missing from a big workshop or a wide-spread work site.

So whether it is stainless steel fabrication, aluminium fabrication, or steel fabrication, this ONE-KEY platform will help you get the things done more efficiently and quickly, with precision.

Modern Computer Aided Design or CAD in metal bending has automated traditional layout for the notch. But if you want to make better parts for your clients and impress them, you should know how these notched are made and measured.

If you could spend some time to learn how it works, you’ll be able to take better and efficient decisions regarding the notch in your metal part. You’ll know which notches are perfect for your job and select it from available ones in CAD menu. Trust me, it’s worth your effort.

The Lesson

First of all, you’ll need to know everything about the mold lines. On a flat pattern or on the drawing, the area of the radius that will be after forming is represented by the distance between two mold lines. Yes, there will be two of them, inside mold line and outside mold line.

But which line is outside and which line is inside?

This depends on which end of the metal part are you working on. Generally, the outside mold lines indicate the flange’s outer dimension and the inside mold line is actually a one bend deduction less. That is the subtraction value of the one bend deduction from the outer mold line location.

Once placed on a flat pattern, the mold lines work to reveal any small feature that lied on its radius. Therefore distort during forming while assuming that you achieved the expected radius in the metal part.

Two Axes, Two 90 Degree Bends

Sometimes, you’ll have two axes, thus two bends. They may be particular to one another. That means the metal part will have 2 side flanges with equal length, which are bent to 90 degrees.

To Layout desired notch, you need to use the mold lines again. Once we get to determine the inner and outer mold lines for each bend, we can define the center-line for them. We can do it by subtracting half a bend deduction.

The actual distance between the inner and outer mold lines is the one bend deduction. And the center-line splits up the distance, only a half a bend deduction for one mold line and another half a bend deduction for the second mold line.

Once we determine the centerlines, it is time for us to identify X-Y coordinates for both outer notch vertices. Now, the very point at which the center-lines intersect transforms to the innermost location. This is also called the top-center location of the notch.

However, if you are notching by your hand, it will be difficult to get the notch right.

But unless you are doing any prototyping work for a new stainless steel fabrication, aluminium fabrication, or steel fabrication project, you won’t even make the layout by hand. It’s just too much work and it’s not even worth it. So take some time to learn how notches work and then apply your knowledge to the corner selection in your CAD system. This will also help you in your laser cutting, metal rolling, welding or any other metal fabrication projects.

Metal rolling is getting more and more complicated since the requirements of versatile angle rolling increases. This is true for every metal fabrication process, especially, metal rolling, metal bending, laser cutting, welding, etc. But lately, the crying need for the massive upgrade in metal roiling process is being noticed by all the metal fabricators.

The next generation of metal bending machines, equipped with automation and other structural upgrades for stainless steel fabrication, aluminium fabrication, or steel fabrication, was introduced by Promau Davi at a conference in October which aims to push the company into the future.

Re-engineered features:

Seeing an opportunity for growth, Orazio Davi the president of the Promau Davi Italian headquarters, decided to change the company’s strategy and opt for a larger investment into the angle rolling market. By doing so, the company intends to make improvements to already existing technology. They accomplished this by investing in a research and development team to implement improvements based on customer feedback. This results in a complete redesign of the company’s angle roll line. Some of the re-engineered features include:

- Radius-Checking System: The most significant improvement to the company’s line of section roll machines is that it now comes equipped with a system called iRoll-camera, which serves as a radius checking mechanism. This allows workers to check and compare the radius of the part being bent with the model in real-time with the help of a camera, without having to remove it from the machine. This has not only improved the safety of the process since parts do not have to be moved around anymore, but it also allows for jobs that require different radii. This is done through templates displayed on a screen that the operator can use while rolling the part.

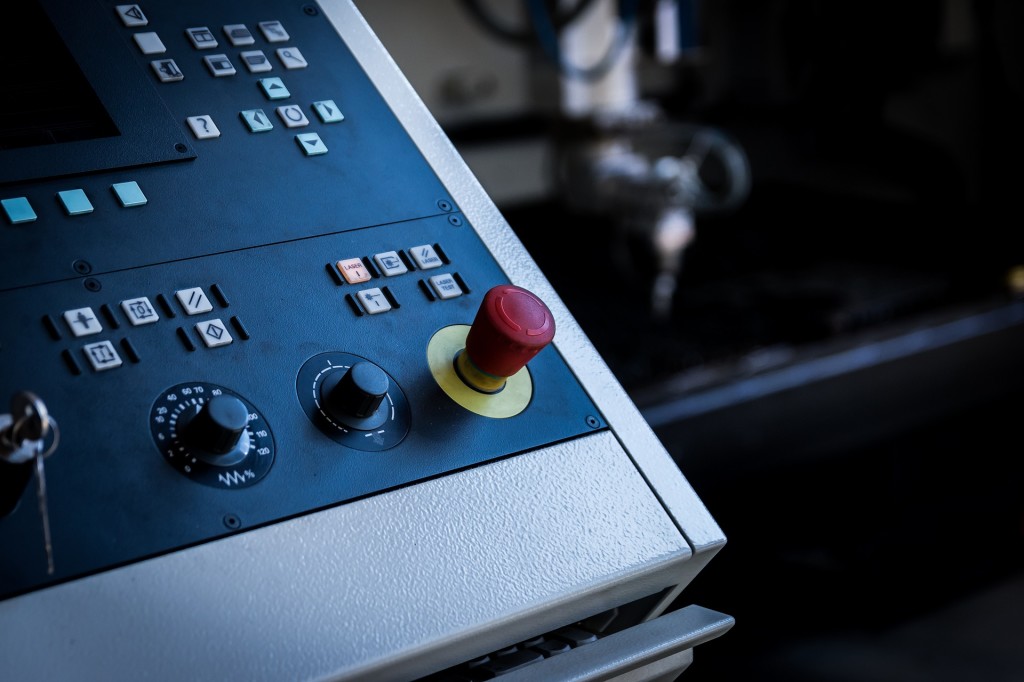

- Auto Learning: By using digital signals instead of analog ones, the independent elements of the machine can be monitored and diagnosed through the CNC. However, this is not new in metal fabrication industry bit t definitely a revolution in metal bending and metal rolling.

- Intelligent Hydraulics: This is a redesign to help the customer with larger part bending needs. The machine has independent hydraulic motors and pumps along with high-torque planetary drives that are attached directly to the rolls. This allows the system to intelligently adjust the torque and optimize the process.

- Compact Design: A redesign of the machine frame has allowed a more compact and safer structure, which helps prevents external damage to the machine. This makes the machine much more durable and sturdy.

- CNC Mandrel Bending: The primary objective of CNC mandrels is to effectively reduce or even eliminate cracking, thinning and other defects that occur during radius bending of thin and hard materials. This technology allows for the tightest possible bends.

All of these improvements are incremental but significant, and thus the next generation of Davi’s new angle roll machines help thrust the company into the future. But this is definitely not the end, it’s just the beginning of a new era of advanced angle rolling.

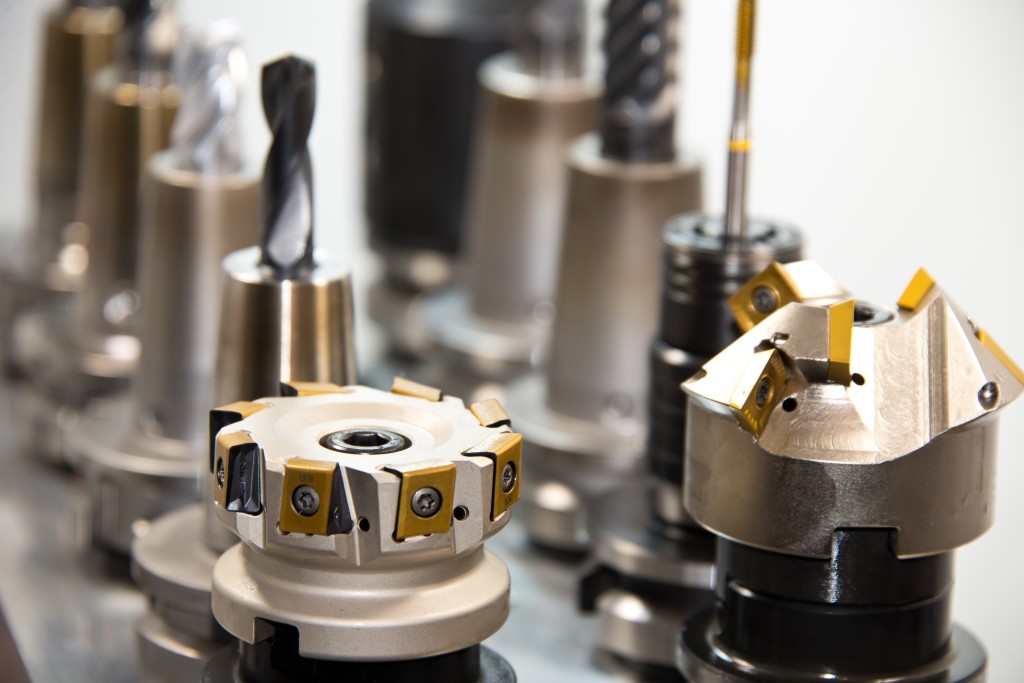

The use of Advanced High-Strength Steels (AHSS) in laser cutting, metal bending, metal rolling, and in the auto has created a new challenge, especially for stamping tools, and the methods used to produce them in metal fabrication.

Tool-Hardening in Retrospect

Various steels that can be hardened have been used as dies for stamping and forming purposes. These have been either forged, cast, or mill-formed. These days, less hard cast iron and cast steel is used for the dies to reduce their cost and weight.

Hardening of the die depends a lot on the size and shape of the die itself. Heating up the die and then quickly cooling it again, often called quenching, hardens it. Afterward, the steel is tempered to prevent cracking, which in turn increases toughness, ductility and extends its life.

Flame hardening used in stainless steel fabrication, aluminium fabrication, or steel fabrication for large dies with more complicated shapes focused on hardening the surface of the die, with special precautions being taken to extend the useful life of the die. Although special coatings are not amply available, chromium plating has been used to protect stamping dies with success for several years.

Due to AHSS becoming harder, the drawbacks of using chromium became more pronounced. Frequent wear and galling means that the dies need to be recoated with chromium after a few runs. This greatly lowers the efficiency of chromium, making it a more costly method preserving the condition of the die used for stamping AHSS. Moreover, slug damage makes repairs much harder on the chromium-plated surface. This damage is extended if the weaker material under the material is exposed for too long, as it wears out faster than the chromium covering it. Finally, compounds of chromium are among the 189 HAP (Hazardous Air Pollutants), which means chromium plating is potentially a significant health hazard.

Ion/Plasma Nitriding

Ion/Plasma Nitriding is a technique which involves treating the die in a vacuum vessel with heaters and a plasma generator. To achieve the nitriding effect, the die’s parts are covered using glow discharge plasma. This new technique, implemented in recent years, produces much harder dies. Moreover, nitriding does not introduce a new layer of protection but provides depth level hardness required to withstand the much greater impacted forces when forming AHSS, this prevents significant slug damage. Furthermore, it does not create any changes in the shape of the die as well since the process ensures that it is applied evenly in all areas of the die.

This technique produces reusable, harder dies, making them a feasible alternative.

If you are lucky enough to pull over into the drive-thru on a rainy day for a burger, you might have benefitted from a common innovation that was made this much popular by the 60% metal fabrication shop at the northwest of Atlanta, a canopy that keeps everything dry.

According to the design manager for Kennesaw, Mr. C. J. Mays, 70-80% of a store’s annual comes from drive-thru. And it is possible that you lose 50-60% revenue due to the weather. Coming from someone who makes canopies on a professional level, really says something.

Actually, a drive-thru usually looks a plain architectural element, which can benefit from flexible tooling. But when you look closely, canopies at most QSRs have a narrow sheet metal panel lookalike extrusion, component that simplifies stainless steel fabrication, aluminium fabrication, and mild steel fabrication greatly.

This strategy of utilizing extrusions where and when possible is the most important element of Uni-Structures’ business plan. Extrusion has been the building blocks to help this business grow.

But surprisingly they added a new 4-kW fiber laser in their mechanical rooster. But the question is, is this investment a step to the inevitable transformation, one of precise laser cutting, welding, metal bending, metal rolling, without the need for design tooling or relying on any extruded shape?

According to C J Mays, this is not what’s happening. Instead, he said that this laser cutting machine will help them diversify and put their skills in special projects, like the ones that use visual elements from the core drive-thru businesses, and yet for most cases, this won’t be repeated anywhere else, most probably.

Signs indicating to the Change

CEO of Uni-structure, Michael Barnes was in the sign business once. When he used to put up others’ sign, he realized how unprofessional these are and the hilarious quality.

Then one afternoon, once he launched his company, he saw that people were lining up in the drive-thrus for rain. They couldn’t go out or keep their windows open for long. So he asked himself whether the people deserve more or not.

He got the answer; yes, they deserve. And it won’t be a joke if I say that they bought their laser cutting machine for one reason only, diversification.

Although before that their plasma cutting system was getting the job done, after getting the laser cutting machine, they have been able to take different projects.

Uni-Structures didn’t buy this new fiber laser just to defeat limit imperatives. The buy was rather a part of the organization’s long-haul procedure.

He clarified that the organization has developed into what it is today without a formal deals exertion. Proprietors and directors assembled associations with developers, contractual workers, modelers, establishment proprietors, and those at the corporate level of a portion of the country’s biggest QSRs. Uni-Structures is on the corporate-affirmed rundown of numerous chains; when the need emerges for a drive-through, Uni-Structures gets a call. All this goes back to the decision of them deciding to buy that laser machine.

It’s a great time for a teacher when a connection can develop between classroom learning and certifiable experience, especially if it’s about laser cutting, welding, metal bending, piercing, metal rolling, or any other technical works. In this type of stainless steel fabrication, aluminium fabrication or mild steel fabrication processes, firsthand experience is what that matters.

Curt Claycomb and the welding understudies of him at Northland Career Center at Platte City, Mo., had a chance to encounter just this in 2015. That is the time when the district of Platte Woods, a little city encompassed by Kansas City, Mo., moved toward the technical and career school about manufacturing a foot-bridge for the Emerson Park in the neighborhood.

The open door coincided superbly with the school’s responsibility regarding making instructive conditions that reproduce true working environments. Northland Career Center, from the very beginning, has been dealing with this style of undertaking based learning in the course of recent years. The objective is to offer their students not just the normal classroom and specialized direction typically connected with their area of learning, yet in addition have them prepared so that they may be relied upon to succeed in their own field, no matter what situation arrives. This would have been a huge deal for its welding class.

Claycomb, the industrial welding instructor said that it was one of the largest bridge, as a matter of fact, anything that they’ve ever built.

This undertaking wasn’t just about consolidating metal tubing to make that bridge. The trainees were in charge of everything. They set up together a basic design-layout, with the assistance of the project called Lead The Way trainees from the Platte County High School, and completed a cost-efficiency evaluation to decide the most practical approach needed to make a bridge deserving of a park. When city authorities endorsed the plan, which featured the utilization of a normally rusting metal that needn’t bother with painting, the students examined the accessibility of materials and set up a healthy relationship with one tube factory in the Southeast that could give and convey to a sensible cost. They likewise masterminded pickup and conveyance of that bridge.

Obviously, the trainees were given the chance to utilize their fabricating abilities. Once more, they took care of the design-related choices. Since they were finishing their inside, they chose to utilize the gas metal arc (GMAW) welding procedure to join the tubing & 70S-6, a universally useful welding wire. They took a gander at the welding wire outlined particularly for the old, rusting steels, at the end of the day chose that such wires were not by any means required, similarly as long as the welders didn’t set down excessively metal.

At last, the greatest takeaway for the trainees was how efficiently they took care of the whole task, as per Claycomb.

The welding trainees demonstrated a considerable measure of energy in the offer to finish the bridge work before the end of their school year.

Similarly as any other future business, like metal fabrication industry would expect, together all the trainees met their due date, and the bridge was conveyed by the setup date. A while would go until the point that the bridge was introduced, however, the center group got together one final time for an official devotion in November of 2016

Claycomb said that he seeks this undertaking opens new opportunities. Brian Noller, executive director of the Northland Career Center, was eager to see the venture include different trainees even outside of metal welding modules.

When it’s about your company’s reputation, there is no other way but to make sure everything is right and top-notch. Whether it is stainless steel fabrication, aluminium fabrication or steel fabrication, getting the job done is all that matters. Sometimes it’s easy, sometimes it’s not. But one thing that makes the metal fabrication process easy is the pre-process state of the metal.

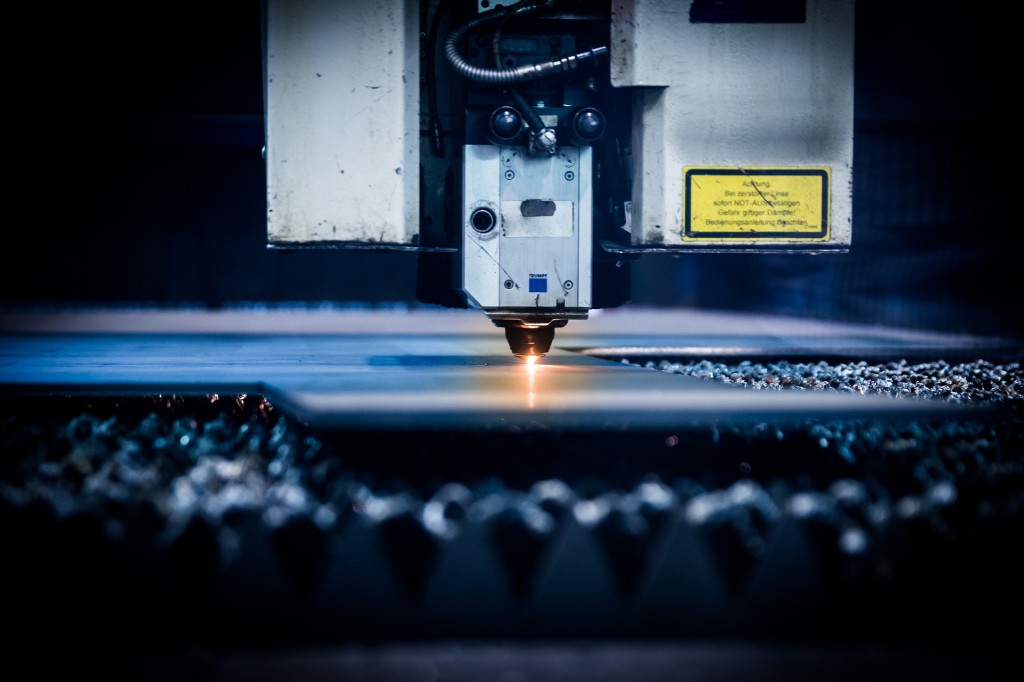

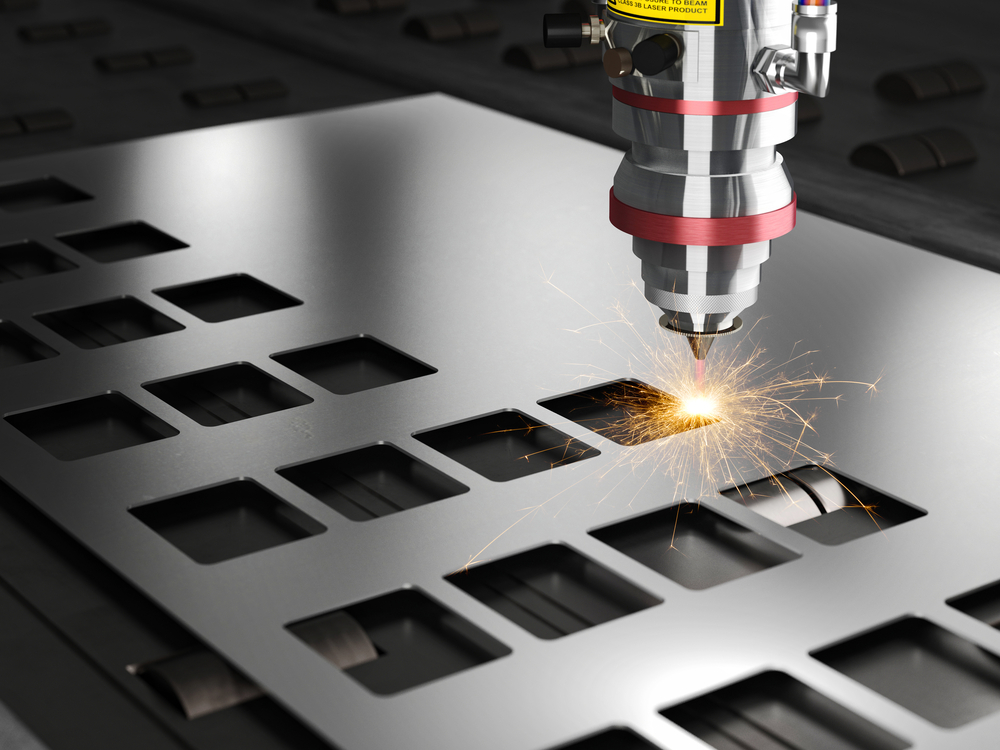

For laser cutting, welding, metal rolling, piercing, metal bending, the state of the material plays an important role. An ideal example will be how a better material surface helps to get a better laser cutting.

Laser cutting machine operators claim that the throughout the consistent thickness of the hot-rolled material has a great impact on the laser cutting performance. If the metallic surface is properly done, dialing on the remaining cutting parameter becomes very easy.

Overall, the lighter-gauge stocks offer more flexibility to the laser adjustment, while comparatively thicker stocks offer small process parameter windows to get a good cutting edge. When the window becomes smaller, dialing in the laser cutting parameter becomes more and more challenging and optimal cutting gets compromised.

Any laser cutting machine operator who pushed the machine to its limits with material-thickness knows it very well. Machine variables abound: laser power, kerf width setting, focal point, gas flow, and gating or the pulsing frequency.

If you ask a laser cutting machine operator, what makes a good material for laser cutting, he’ll reply that the material should be flat and smooth at the same time. But if we talk about precise comparison, cutting parameters are kept at that machine’s factory setting; speed of cutting is the only parameter which changed between the runs.

After hundreds and hundreds of metal plates and sheets, a study was able to quantify what most laser cutting machine operators have been guessing for over a decade.

Yes, the surface of the material has a decent effect on the edge quality, more than any other laser cutting conditions and more than you can think.

This is the reason why brushing black-HR with oils before putting it through laser cutting machine makes some sense. Many metal suppliers even use buffers for dressing the metal surface and oil it after that. This surely helps but this doesn’t remove every bit of loose scale or all the air gas as picking will do.

In the end, everything goes back to giving the laser beam a constant-leveled metal surface, no imperfection, no loose scales, no valleys and pits, nothing that hinders a constant focusing point and a consistent depth that goes with focus.

Yes, I know. The cutting parameters might be different for you and the shop beside you. They actually depend on the shop’s climate and other related factors. This includes a proper preventive maintenance on your machine. Remember, bad optics most probably will give you a bad cut, no matter what so ever, even if the material is fine. But if you provide a smooth and consistent metal to a well-maintained, well-operated laser cutting machine, the results will be satisfying.

Fabrication processes like laser cutting, metal bending, metal rolling, etc. require a great deal of safety precautions. Whether it is stainless steel fabrication, aluminium fabrication or steel fabrication, these precautions ensure that the operators of these machines stay safe from the occupational hazards or any kind of accidents. Besides, these safety measures and tips also help increase the productivity. That’s why, today I’m going to talk about few of those tips, especially for the press brake machines.

Keep the Workplace Clean

Metal bending doesn’t get that messy. But the press brake machine should be cleaned properly to ensure precise bending angle and curves. For that, it’s important that your press brake and the workplace is free of scrap, grease, and oil.

Use assists

Press brake operators should use help and assistance from people in loading & unloading the metal parts or even the heavy sheets. This will let the operator concentrate on the work he is given, which is to use the press brake for bending metal sheets.

Dress Properly

In metal fabrication industry, safety is always a concern. Although press brake is not as dangerous as plasma cutting or laser cutting machines, it still can do a good damage to your body, especially the hand. That’s why never forget to wear thick gloves when operating a press brake with sharp-edged sheet metal. Also, wear your googles and other protective gears before start operating the press brake.

Never leave the machine unattended

Even if there is no one is around the press brake to mess the bending shape, you should never leave it unattended, especially when the sheet metal is on the metal bending machine. Leaving the metal part in the press brake may lead to improper precision to the sheet, resulting in uneven bending.

Keep the distance from the moving objects

Footswitch and cords are tough to with, also every loving object near a press brake machine. That’s why it’s important to keep yourself and others safe from moving parts of press brake machines.

Avoid using damaged dies

Just one sheet and then I’ll change the die.

No, don’t do it. You might be thinking what a damaged die can do to your work. A lot of things, mostly bad.

When you use a damaged die in your press brake, you not only put your machine in danger but also yourself. Besides, when the damaged die works on the metal sheet, it will not work as you would expect. Instead, it will give you uneven bending angles, resulting in a product that won’t compile with your standards. Also, using a damaged die can cause a serious accident. That’s why don’t push your die if it is damaged.

Don’t tamper with the wiring and Safety Control

If you are not an electrician, or you don’t know a lot about press brake’s internal construction, then it is best you keep your distance from the wiring and circuits. Don’t mess with the wirings or the safety controls. No need to be the all-knowing electrician. If you see a problem, wait for an actual electrician to come and fix it.

It’s no shock that industrialization has brought the curse of destruction along with the heavenly comfort in our day-to-day life by the manufactured products. Metal fabrication industry is also not an exception. With the constant advancement in laser cutting, metal bending, laser welding, metal rolling, arc welding technology, the new and improved machinery are consuming more and more energy. And some of the bi-product from stainless steel fabrication, aluminium fabrication, and steel fabrication emits harmful greenhouse gas, resulting in holes in the Ozone layer.

But metal fabrication industry is trying heart and soul to minimize the emission. However, many manufacturers are unaware of what to do to prevent the nature being destroyed from their productive work. So, here is 6 effective tips to help you start saving the earth from right on.

1. Energy-efficient Machinery

- Presses: make sure the presses are equipped with energy-efficient features like servo drivers, energy bank, capacitor, regenerative braking, etc.

- Compressed air: Ensure the leak program in your system.

- Shut down: Your machinery should be turned off when they are not in use.

- Pumps, drives, motors: See if your pumps, VFD (Variable-frequency Drives), and motor are efficient in handling the workload.

2. Facility HVAC and Lighting

- Cooling: Ensure that the cooling system can be changed for necessary reasons. They should be optimized to recover & reuse the temperature.

- Lighting: lighting system in your workshop should have sensors to detect when there are shifts going and when there’s no one in the factory.

- Heating: Like the cooling system, your heater, and boiler should be optimized to recover temperature when needed.

3. Fleets & In-plant Vehicles

- Make the best out of your conveyor system, carted system, and automated guided vehicles to limit the amount of lifting truck that you use.

- Also, make sure that your highway fleet operate is using biofuel.

4. Energy Management

- It is important that you develop energy management plans to ensure minimum energy waste in the fabrication process.

- Participating in demand response program is also very important for metal fabrication shop owner.

- Always use controls and sensors to monitor your usage, working speed, efficiency, and production line.

- If your place has an energy recovery & reuse options to use, it will be a plus point for you to minimize energy wastage and keep the earth safe from the power hunger of machines.

5. Heated Water Recovery

- Another way to save energy being wasted in your factory is reducing the heated water for work.

- While fabricating a metal part, an extensive amount of heat is produced by machines. If this heat can be transferred somewhere else to be used in production process, the energy loss will decrease immensely.

6. Renewable Energy

- Finally, what better way to save energy from being a production waste than acquiring the energy from a renewable source. If metal fabricators can use solar energy, geothermal energy, hydropower, wind power and biotechnology as energy sources for their machinery, there won’t be any power loss, practically because the energy is renewable.

Conclusion: In the 21st century, keeping the world safe from mankind’s destruction has always been a great concern. And it is high time all the manufacturers realized the consequences of their work and look for environment-friendly solutions to their problems.

Metal fabrication industry has grown over the year. New and advanced machinery is being introduced to stainless steel fabrication, aluminium fabrication, and steel fabrication for getting precise results in metal bending, welding, metal rolling, etc. But one thing that has been blessed with innovation most is laser cutting technology.

Laser cutting machines are something that metal fabricators don’t buy every day. That’s why many don’t know what to look for in a laser cutting machine and how to even start.

So, today I’m going to point out exactly what you need to know before getting the perfect laser cutting machine for you metal fabrication need.

Know the Application

The real question should be whether you need a laser cutting machine or not. If you already have an alternative cutting method in your facility, then you must be expanding your services. But if you are not increasing your line of services, think again if you are willing to invest in a new laser cutting machine.

Is the investment in Laser cutting machine worth it?

Most of the metal fabricators who don’t have a laser cutting machine usually give the laser cutting work to other fabricators as subcontracts. If you have a good relationship with your subcontractors, then there is no rush for you to buy a new laser cutting machine.

But if you think that your subcontractor is charging a fortune for his service, it’s time for you to get a new laser cutting machine.

Fiber technology or CO2

In the metal fabrication industry, fiber and COCO2 gas laser machines are dominating since the beginning. Between these two, COCO2 gas laser machines are here for longer than the Fiber. It works by running electricity through its gas-filled resonator and utilizing mirrors to focusing the beam.

On the other hand, fiber lasers have banks of diodes to produce the laser beam. Then the laser is amplified and channeled through fiber-optic cable.

Fiber laser cutting machines are comparatively new in the industry. That’s why it is more advanced. It has low operation cost and delivers higher cutting speed. They also cut more efficiently than COCO2 laser cutting machines. So if you are thinking of buying a laser cutting machine, then fiber laser is the one you should go with.

Do you need new Software?

In most cases, metal fabricators use a software package, which is super popular in general. But the questions are, will it be sufficient to get the work done with your new laser cutting machine? Or a new OEM’s software is a must with the new machine? Even if you buy the new software, what are you getting from it?

As the manufacturing industry is discussing the enhanced interconnectivity of machines, it behooves you to even ask if the latest software is well-equipped to run the machines that are already in the shop, working for years.

What’s cost of having the new laser cutting machine?

This is another factor to be considered while thinking of buying a new laser cutting machine. Almost 10-15 percent of total equipment cost is usually spent on maintenance of the machine.