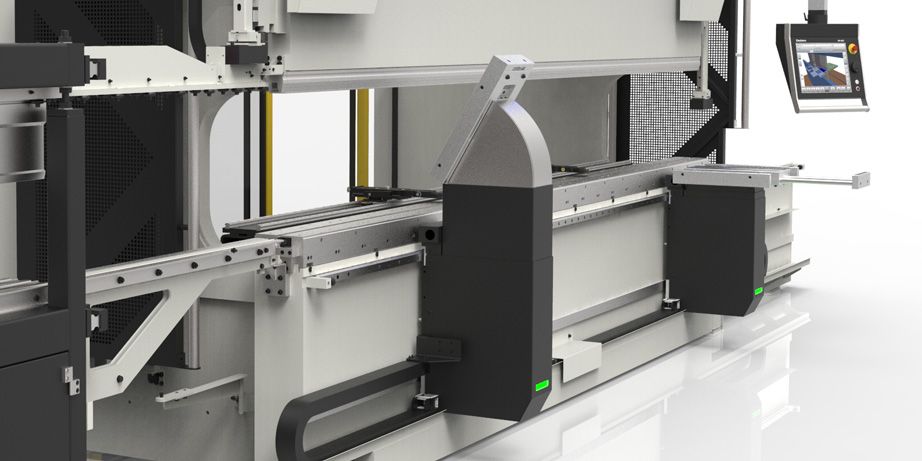

Frequently checking your tools and machine will not only save your money but also save hours of production loss, which can happen if even one of your machine breaks down. Yes, it’s true that machinery problems are very common in stainless steel fabrication, aluminium fabrication or steel fabrication. We see laser cutting machines stop in between a cut, metal bending press brakes malfunctioning badly, welding gears falling apart, etc. in our fabrication shop almost every day. But that doesn’t mean we have to accept those without even trying to prevent the break-downs in the first place.

To save the loss of countless hours of production, it’s important to keep tabs on your machine’s performance and check for faults. Each tool or machine used in metal fabrication should be checked thoroughly for faults and performance issues. Where the process is rather easy for metal rolling machines, welding gears, etc. – for the metal bending press brake, it’s somewhat challenging.

Performance issue with Metal Bending Press Brake

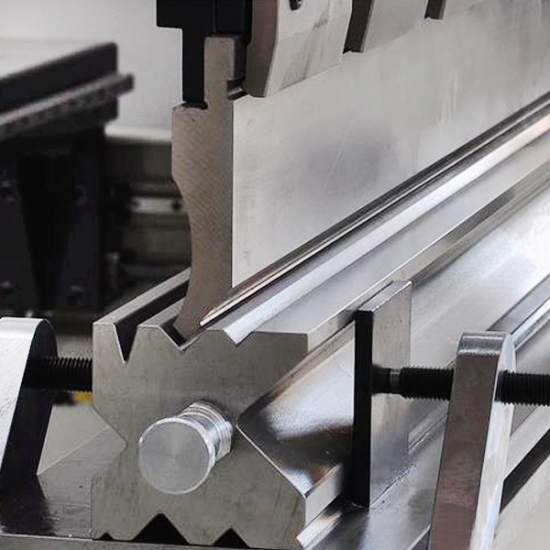

The best way to evaluate the performance of a press brake is focusing on the

- Ram Repeatability

- Reproducibility of backgauge area

- Possible damage on the bed and ram

- Availability of the consistent tonnage

The first 3 of them needs a dial indicator and a mag-base. Check whether the bottom of the ram and the top of the bed is free from any burr or physical damage or not. If there is, your press brake operator needs to clean up the surface with a sharpening stone. But don’t overuse the stone. You are just removing the burrs. Don’t need to put extra effort to make it look like you are modifying it.

Take the dial indicator and the mag-base. Then slowly move them from one end to another while the ram is in a closed position. Doing that, you’ll notice the dial indicator needle is going back and forth as you continue to move towards the minor plain imperfections. There shouldn’t be any movement of the indicator needle move one way while you are moving it towards the center and after that, move to the other way when you start reaching for the other end. If by any chance, this happens, you should know it’s about the ram upset. This type of maintenance requires professional help. Don’t try to fix it on your own.

Then set up the dial indicator again for further reading while the ram is at the bottom. See if the ram returns and gives almost the same reading every time after cycling the ram multiple times.

Next, you need to check is the Tx axis and you can do that by measuring the body if the die you’re about to use and the 2 sets of tooling in the press brake, one at a time. Send the backgauge to the reference position or the origin. Take help of the user manual if you are not aware of the machine. In most metal bending press brakes, it’s four.

Now add half the die body width along the number. Then measure from the front of the backgauge to the front of the die. It should be constant for multiple readings.

Conclusion: These are just the common ways to figure out the recent performing of the machine. For an in-depth analysis, a professional is suggested.