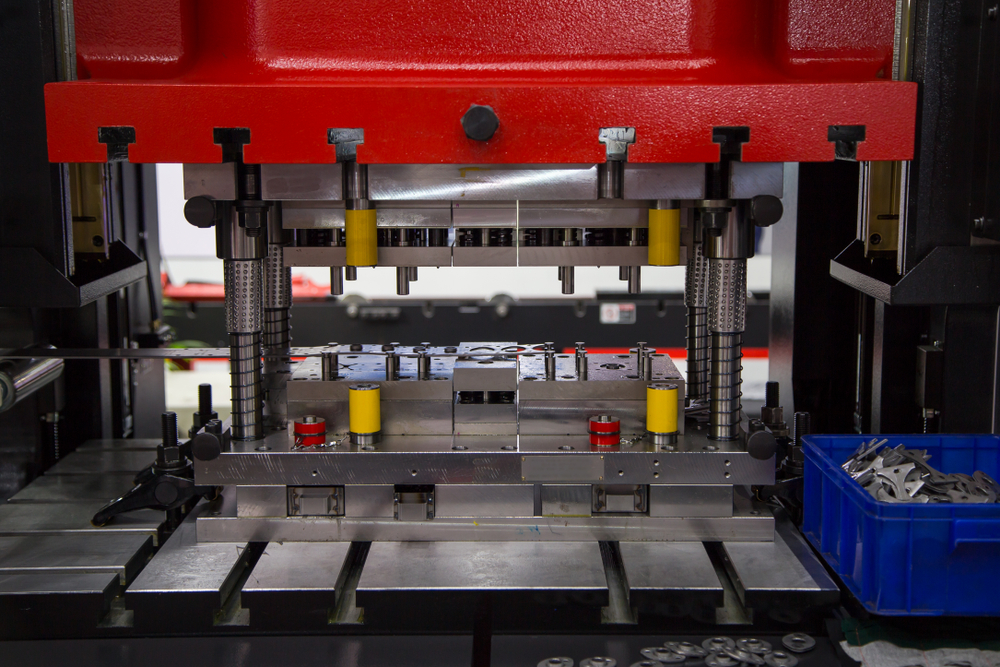

Hydraulic press is a complex unit used for metal bending and pressing. Almost every metal fabrication shop has one of this in their workshop because the hydraulic press is much efficient in its job, which is to bend press sheet metals.

Whether it stainless steel fabrication, aluminium fabrication or steel fabrication, a hydraulic press can bend press any type of sheet metal with precision until somehow the press is compromised.

But in some cases, the compromised hydraulic press can be repaired and used further and in some cases, you will need a completely new hydraulic press to maintain your workflow.

Anyway, how would you know when to move on to a new hydraulic press and when to give it another try?

That’s why I’m here today. I’m going to set the parameter by which you’ll be able to identify the condition of your hydraulic press.

Something wrong with the Hydraulic Press or not?

First of all, when do you know that there’s something wrong with the press brake?

When the press stops coming down to the repeatable depth or when the electrical system keeps shorting out, you should be prepared to do what’s necessary. Maybe repair it or change them completely. Sometimes fluid leaking from its power unit is an indication of malfunction. In this case, your customers won’t take the delivered product because it will have the stain of the machine’s fluid. But it’s a rare case scenario.

Judge by the number

If you are confused whether to replace the hydraulic press or not, then the first thing you should do is look at the numbers.

If only one of the unit or section of your entire machine is malfunctioning, you can simply replace the particular part, which will save a great deal of money than you’d have spent on a new machine.

You should also consider the auxiliary cost of buying a new one, freight rigging, setup etc. So if the problem is with one part of your hydraulic press, maybe it’s not the time to replace the entire unit.

Mechanical Health

Mechanical health indicates to the physical structure of the hydraulic press. This means you’ll have to check for cracks in the structure, amount of clearance in the grinding system among other things.

If you find any crack, it’s time for you to completely replace the unit because this one won’t keep its integrity anyway. So why waste money on upgrading it. Simply replace it.

Hydraulic health

Leaking of oil and lack of depth repeatability is what hydraulic malfunction covers. Besides, dirt and debris getting into the press then blocking the valves is also a recurring problem of the hydraulic press.

For most cases, this type of problems is easily solved by upgrading the respective unit in the machine. There’s no need to replace the entire press for oil leak because it can easily be fixed. But if you want optimal work speed and don’t have any problem spending few grand, you can always get a new one.

Other minor problems

Your press brake may need minor tweaks here and there. These are so minor that upgrading the unit completely is simply a waste of your money, like an electrical malfunction. Electrical problems can be tweaked very easily. You’ll only need a good pair of hand and eye to get it fixed. No need to replace the unit.

Conclusion: Whether it is laser cutting machine, metal rolling machine or metal bending machine, they need to be monitored regularly before thinking of replacing or worse, scrapping it completely. This way, metal fabricators can save the unnecessary cost of buying new machine for no good reason.