In metal fabrication, moving the metal parts is a major responsibility. Sometimes it can be hard and risky for the operators to carry heavy or sharp metal parts. But stainless steel fabrication, aluminium fabrication, and steel fabrication are all about these heavy and sharp metal parts. So metal fabricators had to look for an easier solution to carry and assemble these risky parts – vacuum cups.

Depending on the size of the vacuum cups, they can carry sharp or thin edged parts for laser cutting, metal rolling, metal bending and big or heavy parts for assembling, welding etc.

These vacuum cups have genuinely brought a revolution to the automation in assembling and carry process.

Vacuum cups, not suction cup

There is a common misconception about the vacuum cups. People mix it up with suction cups. Suction cups are pressed onto the metal part and then the suction cup seals with the part itself because the air inside is expelled. But vacuum cups works differently. A pneumatic vacuum generator along with a venture is employed by the vacuum cup for action. In this process, compressed air is present and they create a vacuum to hold or grip the parts used in a metal fabrication process.

Characteristics of Vacuum cups

Vacuum cup shape, size, durometer, and its tread design all have a major impact in rapid pick-&-place exchange applications. These vacuum cups must have the capacity to clutch the board dependably amid the most stressed points of the computerization’s increasing speed and deceleration stages.

Style and Shape also have its influence. The most used and common vacuum cup has a round shape. Be that as it may, if the cup must grip a sleek rail around any car window or door, for instance, an oval-shaped cup may be required. Ringer molded vacuum cups likewise are accessible for clinging to curved or arched surfaces.

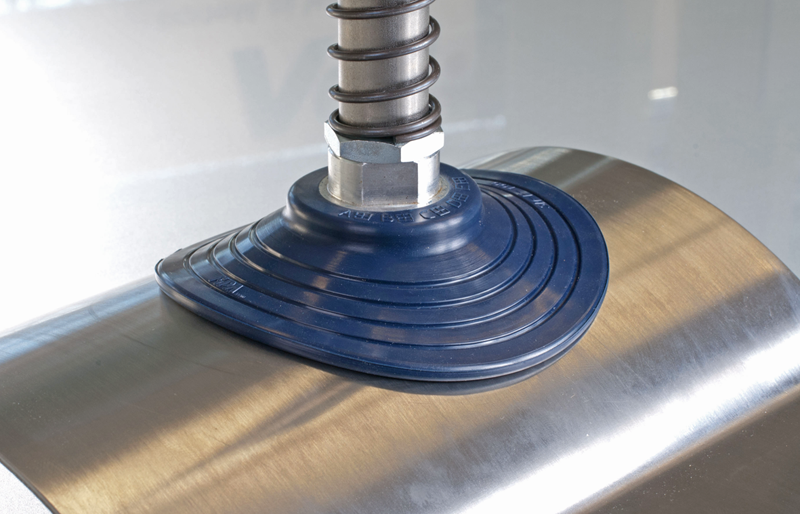

Within these shapes, there are 2 styles: bellows and flat. The bellows-styled vacuum cups are collapsed like the accordion, which gives it the adaptability to pick up things with a sporadic shape or the ones that are not all around lined up with the cup. In these cases, a higher vacuum stream is expected to expel the bigger volume of air from inside. A flat vacuum cup is not as adaptable as the bellow-styled cups. However, they can make a solid grip with minimal air departure.

Durometer is another concern for the vacuum cups. A durometer is usually accompanied to the measurement of hardness in rubbers, elastomers, and polymers. The hardness of most vacuum cups is tested with the Shore A scale. The higher number it gains, the harder the material.

Tread Patterns for vacuum cups are quite distinctive. Vacuum cup providers have made up their own particular one of a kind tread designs that help decide the holding force or grasp of a vacuum cup on the metal part’s surface. A vacuum cup that works in a specific application may not work for others, particularly if the part’s or sheet’s surface is slick dry. Some vacuum cups’ treads are accessible in numerous durometers to get a better grip on the part.

Conclusion: As you’ve realized by now, these vacuum cups are specific to the applications. That’s why metal fabricators need to ensure that they’ve chosen the right one for their need. Otherwise, the production line won’t be as productive as it would have with these simple and small suction cups.