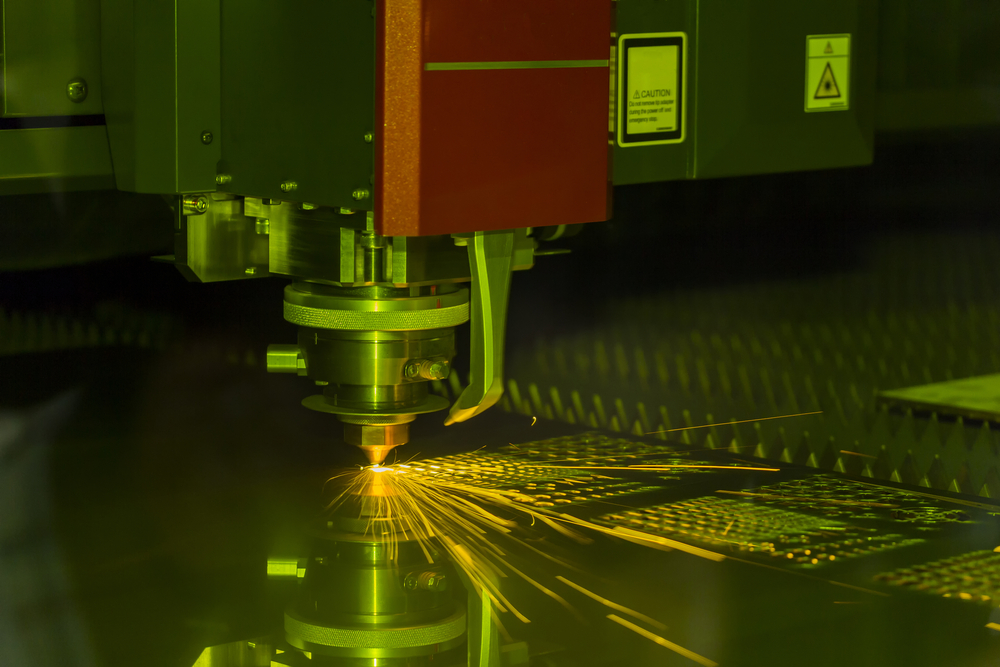

Who doesn’t want a precision plasma cutting? It’s shiny, glossy, and it works exactly how you want it to. You get minimal edge rounding & washout with the precision plasma cutting.

Since the development, mechanized precision plasma cutting made a long way. Although the approaches were different depending on the system, technology that led to the advancement of plasma cutting has similar ingredients: a shielding gas, a plasma gas, and the guide that allows to create just the right energy and pressure levels to cut precisely.

Cutting Challenges

Traditional Plasma cutting machines tend to leave a rounded-top edge and the edges aren’t perfectly squared, unlike laser cutting machines. These edges also pronounced lag striations while the torch “pulling” its arc along.

This lag usually causes challenges for the sharp corners, especially in materials re thicker than 0.5 inches. When the top of its arc makes a precise turn, that lagging bottom of the arcs is pulled around, resulting in rounded corners. But unlike metal bending, welding or metal rolling, the slightest mismatch in the edge may not give you’re the product you are supposed to deliver.

That’s why metal fabricators developed cutting programs that tell the torch to slow itself before it can reach to the corners. You can’t compromise with the precision for any metal fabrication process of any sort. So the metal fabricators had to develop these programs.

There is another challenge with such interior features such as, slots, holes, etc. that involve dealing with a lead-in & lead-out of the cut. For avoiding even the slightest amount of extra material on the corner, the technicians program their plasma cutting machine to cut a little beyond the starting point. This leaves a tiny area that’s essentially cut twice, washing out a little more material which is compared to the rest of the kerf.

Gas Flow Ballet

The precision plasma cutting technology has changed these challenges through gas flow ballet, for better of course. After the precision cutting is introduced, the challenges are minimized through something you can call a swirling gas flow ballet along with electrical resistance as the music.

The Main Players: Hydrogen, Nitrogen, Oxygen & Air

The VP of an ESAB Company, Global Plasma Automation for Thermal Dynamics, Mr. Dirk Ott stated that they have perfected the gas flow and pressure over the recent few years and added that there are multiple approaches to mix out the gases, whether it is shield gas or plasma gas for improved surface finish. This is great news for metal fabricators. But they should also remember that the values are constant for all fabrication projects.

For instance, in stainless steel fabrication, plasma gas usually works well for material with 0.375 inches of thickness or less. But for thicker material, there are different mixtures of gas like F5, H35, etc.

Similarly, for aluminium fabrication, things are not the same for all material. Nitrogen with plasma gas along with water gives an optimal cut and the conditions are different for steel fabrication too.

But only the right gas won’t do the trick. Fabricators need to bring the perfect gas mixture, automation program, and steady operators to get the cut they need and deserve. Otherwise, the motive of precision plasma cutting won’t be successful.