Ergonomics is considered as a nice-thing-to-do in the USA for a long time. But countries in EU, Canada, Australia and few other countries have made ergonomics a law that is a must to abide by. In those countries, the offending business must pay the fine if they do not adhere to the rules, guidelines, and standards. Although Ergonomics in countries like the USA, Singapore, Thailand, India, is still voluntary, nowadays it is not only a nice-thing-to-do. Instead, it has become a must-to-do for metal fabrication industry.

As with most of the business-related decisions, installments of ergonomic machinery and tools come down to the figures and number. Although installing ergonomic equipment costs a lot of money but that doesn’t compare to the cost of accidents and injuries, as well as the compensation for the worker’s medical expenses. Also, the loss of productivity will add to the costs of an accident or injury of your employee.

Apart from saving the expenses that I just mentioned, ergonomic tools and machinery will also increase productivity by reducing wasted movements that consist of lean manufacturing.

Accidents and Injuries Cost Money

MMH or Manual Material Handling injury continues to lead employees’ compensation claims and all their associated expenses according to 2017s Work-place Safety Index, made by the Liberty Mutual Institute for Safety.

The expense of lost-time injury varies, but on average, it is $25000 for each incident. So by preventing one single lost-time injury can definitely save you more than what you would spend on ergonomic equipment.

This particular problem is spreading and it isn’t confined to any single sector. But the industrial workplace report indicates a high amount of MMH lost-time accidents and the employees’ compensation claims, showed by the US Department of Labor.

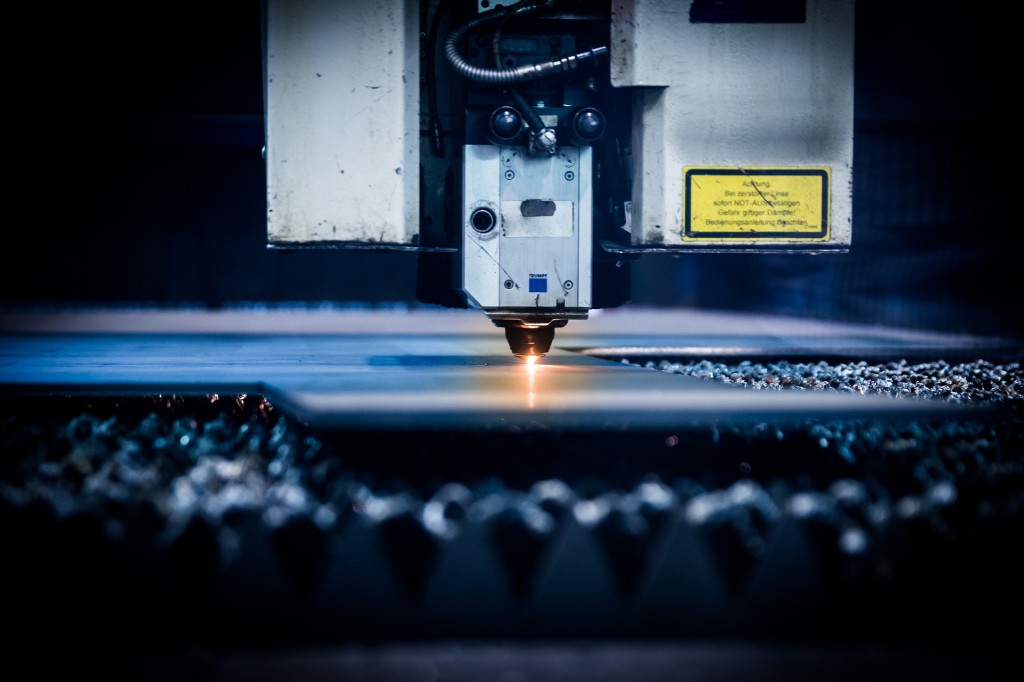

Sometimes these MMH accidents and injuries are incorporated with the poor ergonomics of laser cutting machine, metal bending machine or any other metal fabrication related equipment. The poorly designed workplace and inappropriate manually-handled machines can put your employees at risk. This results in a loss of productivity, lack of quality in production, lost work hours, massive medical cost including compensating claims.

A lot of those claims are results of the accumulated traumas, not any single accident. This includes sprains, tendonitis, strains, and even back pain. This type of injuries usually derives from repeated or excessive stress on the hands, ankles, wrists, elbows, shoulders, and back.

For example, heavy objects should not be lifted from a low angle like the pallet or the floor, bending over in the containers, wire baskets, tubs, etc. should be reduced.

Better Ergonomics Increases Productivity

A well-trained, dependable, productive, creative worker is a standout amongst the most important resources a Metal Fabrication company has. At the point when a worker is missing, notwithstanding for transient damage, the special abilities he or she has created are not supplanted by an alternative. Quality, productivity, and efficiency would all be able to endure. These indirect expenses can without much of a stretch surpass all medicinal expenses.

Often the ergonomics upgrades come in form of a simple upgrade. These could include versatile, easy access machines that help your employees to get rid uncomfortable working positions and reduce bending, lifting, and reaching.

So before the medical expenses and loss of productivity pile up on your annual revenue, it’s time to adopt ergonomic equipment for laser cutting, metal bending, metal rolling, and all other Stainless Steel fabrication, Aluminium fabrication or Steel fabrication related works for the best long-term outcome.

“We’re going to build our steel and aluminum industry back,” Trump said.

Demonstrating what he said, United States President Donald Trump recently stated that he would impose massive tariffs on imported steel and aluminum, while Canada and Mexico, being the primary trading partner of US, will be devoid of new tariff rules on national security ground.

An investigation by the Secretary of Commerce suggested that steel imports threaten to hinder the national security and hence recommended to impose tariffs.

Stocks of domestic steel and aluminum producers in the US brushed up immediately after the news. Tariffs may profit US steel and aluminum makers, yet other nation might strike back in response and possibly raise the expenses for American shoppers. While the Pentagon stated that the US only imports about 3% of total steel it uses and hence it is likely to have no risks involved.

Some metal fabricators may have given thumbs up to the judgment, but some economists believe that tariffs would be a big blow to the employment. Majority of Fabricating related associations have opposed the idea of the tariff. According to them, steel may or may not have been purchased domestically, but tariffs would affect the supply chain because everything revolves around the cost of a product.

According to Mark Perry, Professor at the University of Michigan, domestic steel manufacturers are at bay in comparison to the Asian manufacturers. Increased Input prices and low profit, sales and market shares will be a blow for American manufacturers.

Fabricators & Manufacturers Association, International (FMA) President and CEO Ed Youdell said, “One likely result of this action is to add headwinds to the market for American-made fabricated metal product producers. Just when this market had some sustained momentum, the specter of retaliatory duties and tariffs now hangs over this important manufacturing sector. The association is concerned that jobs and job creation are at risk; those countries affected by this announcement will likely choose to circumvent the tariffs by producing and exporting low-cost fabricated metal parts rather than exporting steel and aluminum.”

The tariffs could altogether have different monetary and political outcomes, depending on countries affected. The news walloped Asian nations like South Korea, one of the highest suppliers of steel, on the other hand, metal fabrication in Singapore and that of Malaysia’s shares rose after the tariff exemption. China, though most top exporter of steel in the world, sums to only 2.9% of steel imports in the US. To curb this loss, China can build new export markets in Asia. A source at a global trading house in Shanghai said: “We believe the fabricators can divert their exports to other Asian countries if the US situation plays out as they expect,”. A metal fabrication company in Singapore, an Aluminum trader, stated that it would be tough for China to export metal fabricated products to some Asian countries due to their import duties.

Metals are produced in excess in Asia, and hence the prices may drop due to the tariffs fiscal, which is ultimately an advantage for the customers. With the change in rate, China will have competitors like Ukraine, Russia, Turkey, Middle East etc. although the strong domestic requirement of steel will be a sign of relief for Chinese manufacturers.

Tariff on metal fabricated products might be a complicated issue, especially after 2008 financial crisis. It is worth noting how other countries and their fabricators react to it take steps to curb their export cut.

For different metal fabricators, the term “cleaning metal surfaces” has different significance. For some, the finishing of metal structures is extremely important and for some fabricator, the finishing may not be a great deal to pay attention.

That’s why the importance of metal surface cleaning is different to each. But in most cases, a quality product is something that not only has a durable construction and an efficient functionality but also a smooth finished surface to look at and feel.

This process of metal surface cleaning can be overwhelming especially for the metal fabricators which have powder coating and painting lines. This is because of the headache of pretreatment systems, which requires intense oversight that ensures the chemical creating the perfect surface for powder and paint so that they can properly adhere.

Other fabricators may do the surface with power tools and welding but they know that a clean surface requires a lot of resources. So, to make a surface perfectly smooth, a lot of resources, as well as time, is wasted. That’s why laser has been a proven an effective way to get smooth surfaces. To be honest, Laser changed the way how fabricators thought of cleaning metal surfaces.

This laser system wipes out residues, contaminants, and coatings with the help of the high-energy fiber laser source. The same type of power sources is used in laser cutting and other laser equipment in the fabrication industry. The best possible way that someone can reduce production cost is by implementing the best equipment and best process.

This process is generally meant to minimize the use of Chemical & Abrasive for cleaning the metal surfaces. The fabricator will place that part to be cleansed in the Class one enclosure and then starts the cleaning program. Once everything is set up, the machine operator will choose between a customized pattern that meat certain surface specification and a preinstalled cleaning pattern throughout the process. The machine operator can also customize the program to include different passes using different values for frequency, power, and the speed on each laser pass. He can arrange a database so that he doesn’t have to remember a metal surface cleansing job that was done previously.

Another great feat of this laser cleaning is it can clean almost any type of metal surfaces that you want, like steel, galvanized steel, stainless steel and even copper and brass. Another interesting fact about laser cleaning is it can even clean reflective surfaces like glass. Apart from metal surfaces and glass surfaces, the laser can be used to clean nonmetallic materials like rubber and plastic.

But the laser cleaning isn’t limited to the flat surfaces only. Recently, the laser is being heavily used in curved surfaces too because the cleaning units are designed in a way that can clean hard-to-reach areas of 3D objects.

Most of the laser systems have a precise cleaning head, which allows the trajectory beam to pass through a certain static path. To clean the surface, the object needs to sit in X and Y axis of the cleaning chamber and then the movements ensures that the surface is fully exposed to the laser beam. This is how you get the smooth and clean finishing to the metal surfaces.

Are you planning to design a structure with non-standard structural components? Are you in need of an experienced metal fabrication company for your big project? Need a fabrication company that can take care of drawing, designing, and manufacturing of structures and platforms and shapes your project? It’s vital you hire the right custom metal fabrication company as they are crucial to a project’s success or failure. Here are the few factors that you must consider while choosing the metal works and metal fabrication company for your project.

Local Proximity

It is not a critical factor but having a fabrication company in close local proximity has few benefits. One of the most significant benefits that geographical proximity offers is logistics. A local company is familiar with the logistics of the buildings in the area and the building codes as well. Moreover, a local company nearby will allow you to conduct project meetings with ease. For example, if your project site is based in Singapore, it would make sense to work with companies like FMB Trading and Engineering, a metal fabrication company that is familiar with the building codes and the area throughout Singapore.

Industry Experience

A little bit of homework before finalizing a metal fabricator can go a long way. Before you finalize your metal fabricator, make sure you study their portfolio and assess if they have worked on similar projects before. Each industry has its unique compliance protocols and regulation procedures. A metal fabrication company with substantial experience in industries such as chemical, biotechnology, food processing and manufacturing will be familiar with these strict guidelines and specifications. Such experience and knowledge empower them to handle the most demanding requests with ease. If the customers of these fabricators are satisfied with their services, you should definitely add them to your vendor shortlist.

Resources to Handle the Project

Gauge if the hired company is equipped with resources to support your project throughout all the phases whether its design, fabrication and steel erection. If they lack the resources to carry out all the stages, are they going to outsource any phase of the project? A metal fabricator equipped with capable internal resources can offer critical insights into any nuances that your building may offer. Assessment of the fabricator’s resources will also help you gauge their capability of completing the project promptly reducing the risk of project downtime.

Safety Standards and Protocols

A fabricator that aims to deliver quality services to their clients always follows the best-practices and the protocols that come with it. Ensuring personal safety for the employee as well as the visitors is one of the most critical safety standards that successful companies follow. The safety standards and protocols they follow will help you gauge their safety score and the quality of process and execution they implement in the project. Any company that adheres to strict employee safety will adhere to strict quality control standards as well.

Materials Used

Good metal fabricators utilize materials of the highest quality. The assessment of the grade of structural stainless steel or metal alloy vital for the completion of the project gets overlooked in the early stages while choosing between the fabrication shops. Competent metal fabrication companies ensure you understand what materials they will use for your project and why.

With a diverse experience spanning across various industries since 1992, FMB Trading and Engineering have completed and managed most complex metal fabrication projects across Singapore. We have the capable in-house teams and a treasure of resources at disposal to meet customers’ needs and offer customized fabricating services. Contact FMB Trading and Engineering to discuss the details of your next metal fabrication project in Singapore.

Stainless Steel and Galvanized Steel are two of the most commonly used metal for production. They have some similar characteristics and only a few difference, especially in their composition. But their application is quite specific. But many industrialists face a dilemma when they have to choose either one of them. That’s why today we’ll explain who should use Stainless Steel and for whom, Galvanized Steel is best. But before that, you should know their significant characteristics and why they behave is such way. Both stainless steel and mild steel can choose to be cut by laser cutting, or bent by our bending and rolling machines.

Stainless Steel

Stainless steel is also known as Inox steel and it an alloy of 10.5 percent Chromium & Iron. Iron is its main component but the added Chromium creates an extra thin Chromium Oxide layer on the surface of the iron. This layer is known as the Passive Layer, which is the signature characteristics of stainless steel. This passive layer prevents any corrosion over the metal surface. And the more Chromium is mixed to the alloy, the more resistance against corrosion and oxidation becomes inevitable. Besides, there are other elements like Silicone, Manganese, and a good amount of Carbon added to the Stainless Steel. Besides, Molybdenum & Nickel are also added to enhance formidability and few other useful characteristics.

For extreme resistance to corrosion and flawless finish, Stainless steel is used in pharmaceutical and culinary industries. Stainless steel is way better than galvanized steel in terms of the surface appeal. The physical composition of stainless steel makes it long lasting and that’s why stainless steel is used in those industries where the product needs to maintain its integrity for a long time. The lack of any type of rust or layer keeps the surface smooth and shiny for a long time. In short, stainless steel is much more durable and strong than galvanized steel.

That’s why many industries use stainless steel as their raw material for production. Here are some of the most common applications of stainless steel in different industries where the manufacturers understand stainless steels potential.

Applications of Stainless Steel

Architecture: Architectural use of stainless steel is not new. For stainless steels anti-vandal characteristics and the low-cost maintenance, they are being used in modern architectural infrastructures. Mainly stainless steel is used for roofing, cladding, and facades in houses. Nowadays, stainless steel is proving itself to be quite efficient as the main structure for buildings because of its durability.

Cutlery: As mentioned earlier, stainless steel is completely rust proof and that’s why they have smooth and clean surface. Because of its shiny and appealing surface, stainless stereo is being used as the main raw material in the cutlery industry.

Power generation: The resistance again corrosion in hot temperature is a useful characteristic if stainless steel. That’s why power generation industry uses stainless steel for their ventilation shafts and in gas and steam tribune. The stainless steels with low cobalt are the ones to be used in nuclear power plants.

Chemical, Oil, gas industry: One of the industries with their constant want for stainless steel is chemical, oil, and gas processing. In this industry, starting from the tubes and pipes up to the storage tanks where gas, chemical or oil is stored, are made of stainless steel. Especially stainless steel’s 304 grade is of great importance to the industry and that’s why it is considered to be in the most important sector for stainless steel.

Automotive: Stainless steel is used in automobile industry for its low impact on the environment, low maintenance cost, and the minimum life-cycle cost. They are used to make the vehicles structures, exhaust system, catalytic converter, etc. And it seems like, the use of stainless steel in the automotive industry will most likely to increase.

Medical: Surgical tools for operation needs to stay hygienic. That means they can’t have any rust on its body. That’s why stainless steel is a preferred for Surgical equipment.

Sculpture: Metal sculptures are a form of art. This art is also backed up by the use of stainless steel. Many designers chose to use stainless steel for the sculptures because of its durability and

Bridges: Like building a structural frame, stainless steel can also be used in bridges where they need a material that is long lasting yet cost-efficient.

When you shouldn’t use Stainless Steel

In places where two pieces of steel parts may need to collide or rub together, stainless steel should not be used. Because friction breaks down the passive layer of stainless steel, making it lose the resistance to corrosion. Another place where stainless steel won’t be an ideal choice is the place with chlorine. Chlorine also breaks the oxide layer that removes stainless steels’ “stainless” part. So any places with chlorine bleach isn’t an ideal place for stainless steel to keep its integrity.

Galvanized Steel

Galvanized steel is simply a carbon steel variation that is dipped in molten zinc. The process is called dipping and that’s why galvanized steel is often referred to as dipped steel. The main benefit of galvanized steel is they are corrosion resistant like stainless steel.

Due to the added layer of Zinc, Galvanized steel is mostly used in places near water. Because the layer of zinc prevents carbon in the steel to react with salt water. So no chances of rusting. That’s why, workstations around 5 miles radius of the coast, should use galvanized steel.

Application of Galvanized Steel

Construction: Galvanized sheet metal is used for verandas, support beam, street furniture, staircases, ladders, industrial walkaways, fence, handrail, ductwork, canopies, building frames, balcony, awing, etc.

Electronics: To make computer cabesings & the precision instruments rust- and moisture-free, manufacturers use galvanized steel.

Bolts, Nuts, Nails: Galvanized steel is used to produce nails, nuts, and bolts to make them rust proof.

Piping: Galvanized pilings have been replacing lead and iron in cold water plumbing since the early 20th century. Because galvanized pilings can maintain its integrity for 70 years on average in such conditions.

Playground Equipment: Kids play equipment like swing sets, jungle gyms, bicycle racks are made of galvanized steel for its resistance against rust.

Transportation: Aircrafts and cars have a rather large demand for galvanized steel. The manufacturers use galvanized steel to make spring housing, seating, roofing, parking brakes, oil pans, fenders, hoods, etc.

Wire Rope: Another common use of galvanized steel is in high stressed wire ropes.

When you shouldn’t use Galvanized Steel?

Although galvanized steel is much effective against water and humid atmosphere, it loses its resistance against rust when it maintains regular contact with salt water. Besides, Galvanized steel nails shouldn’t be used while building a cedar fence. Because the naturally occurring enzymes in cedar react with zinc, making black stains on the fence.

Which one should you choose?

Galvanized steel and stainless is very similar when it comes to their characteristics like rust-resistance. But stainless steel is much more efficient in protecting the metal than galvanized steel because the outer zinc layer will eventually wear off.

Besides, stainless steel is much more durable than galvanized regular carbon steel. So, stainless steel is the clear champion here.

But if you have a small project at hand or want to cut a slack from your manufacturing/production cost, galvanized steel can be your pick. Because galvanized steel is much cheaper than stainless steel.steel is much cheaper than stainless steel.

People refer to quality assurance as a process of evaluating and testing the products before they leave the factory. With physical products, the process involves acceptance sampling, stress testing, statistical press control, and error proofing among many other things. The aim of this assurance test is to make sure the customers are getting what they ordered while ensuring minimal variation to keep the model’s integrity. Since people realized the precision and efficiency of laser cutting in the early 1960s, industrialists are looking for ways to implement this cutting-edge technology to their respective industries. That’s why, from clinical to aerospace use, laser cutting is ruling over metal integrity without raising any questionable eyebrows in case of profit. Laser cutting is usually the first step of the process before it continues down the line to undergo metal bending, metal rolling, and other types of metal fabrication in stainless steel, mild steel and aluminium.

The company maintains there quality by evaluating each batch of production. This way, the company can know where they are wrong and they can fix the issue before the product reach to the customer. Also, they do not make the same mistake with their products in future.

Although it may seem like quality Assurance is a way to find faulty products, actually, it is a way to make sure your customers are getting what they deserve. That’s why no company or business should avoid the quality assurance because this process can help them grow and produce better products for the customer. Here’s why Quality Assurance is important to any company.

Finding defective products

The best and most important reason why companies should take quality assurance for granted is finding the defects. Defective products are harmful to any business for two reasons. First, the customer who got your defective product will never purchase or take your service anymore. Secondly, they will make bad mouth-to-ear publicity to their friend and family. This way, you are not only losing the customers whom you delivered your faulty products but also, you are losing hundreds of potential to-be customers before you know it. Even if the fault is a minor defect, your customers will see it as a big deal. There’s no escape from it.

And even if you don’t intend to deliver a faulty or defected product, by mistake, they can reach to your customer’s hand, if quality assurance process is not maintained properly. So why loose customers when you can increase your business by delivering top-notch high-quality product to every single customer of yours. So, to find out and separate defected products, quality assurance has no other alternatives.

Culture of Quality

If your employees are dedicated then you are one of the luckiest employers out there. But, not all are as lucky as you. Some of the employees don’t pay attention to the production process and that’s why they some of the product come out as defective products. But if they are told about the quality assurance process, they will be alert and conscious. They will start producing the product with more care because they that if the products are faulty, they will get scrapped in the quality assurance process. That’s why they will become more careful and you will get quality products.

Scrap Reduction

Q Quality Assurance is a process where manufacturers can identify defective products. Some of them may only have a minor problem and some of them with major defects. The products with major defects are thrown as scrap. But the ones with minor manufacturing faults can be fixed with little time and dedication. Once they are fixed, you can deliver them to the customers. This way, you can reduce the amount of scrap product. The more you save, the more you protect your business from loss.

Time Efficiency

Quality assurance team is separate from the production unit. If there is no Quality assurance team in your factory, your valuable production unit will have to check for defects in every product they produce. This is time-consuming. Besides, it’s not an ideal use of the production force because they are much more skilled to just check the products for the defect. It is also a waste of their skills too.

But if you have an experienced quality assurance team, your production unit won’t have to look at the product to find defected items. You will save a lot of time of your skilled workforce. Besides, their experience and skills won’t be wasted on such non-productive work.

Increased Customer Satisfaction

Quality assurance team makes sure that every product that comes out of your factory, is built with high-quality material and they are accurate in shape, size, type, and function. That means any product that passes through your quality assurance team is the best quality that your production team can offer. No defected product will pass from your factory, only the good ones will go on the delivery truck.

When these products are delivered to the customers, they will get the best products from your factory. This will make a good impression of your company to the customers. And if the customers are satisfied, your sale will increase automatically. They will remain loyal to your brand and this kind of mouth-to-ear publicity is the best type of publicity that any brand can get. That’s why, for client satisfaction, Quality assurance is a must.

Improved Employee Confidence

A company’s employee works very hard to give its best to the company. But they hardly realize the work they are doing is good or not as good as the company would expect. That’s why they stay in dark about the product’s quality. But if the products go through quality assurance process, they will know what’s happening with his works.

When the product goes through the quality assurance process, they are divided into good products and bad product. At the end of the day or after a batch, it is possible to calculate the ratio of good products and the scarp ones. And if the production workers are being informed about their success ratio, they will feel good and confident about their work. As a result, they will work with enthusiasm and confidence.

Bottom Line

Quality Assurance is an inseparable part of any good company. Without it, there is no actual way to figure out if the work you are doing is standardized or you’re just making scrap products.

Although it might seem like a way to identify defected products, in reality, it is an actually a way to separate the good works from the faulty ones. That’s why there shouldn’t be any question about whether quality assurance is important or not.

Structural stainless steel is one of the finest and highly sustainable building materials utilized in various industry functions. It finds application in construction, oil and gas, manufacturing, infrastructure and many more industrial sectors. This versatile metal is the preferred building material for metal fabrication specialists and metal works industries across the world. It is cost-effective and offers great mechanical functionality. This quality of structural steel makes the building process swift and simpler. So, let’s take a quick look at why structural steel is considered as a preferred material for the fabrication process in shop floors.

Strength & Durability

Structural stainless steel is tensile i.e., it has a high strength to weight ratio. It also weighs less compared to other metals used for fabrication. It’s also stronger compared to other building materials, even concrete. These attributes make it easy to work with. Its strength also makes it reliable to withstand and resist any types of disasters such as fire or storms.

Another key attribute that helps steel take precedence over other building materials is its long lifespan. The final product fabricated from structural steel is strong and capable enough to withstand any external pressure. It is capable to withstand wear and tear of all kind of weather conditions. This significantly reduces the headache of maintenance of the buildings and equipment.

Flexibility

Steel can be bent or molded into an endless number of shapes, thanks to its malleable and ductile nature. This makes it an ideal material for preparing custom designs. Structural steel, being an alloy, can be adapted to give different properties Designers can work on various designs ranging from simple to complex with ease, making it a popular choice in the construction industry. It offers designers a flexibility to make changes in the planning stages without impacting the project cost.

Speed of Construction

Structures that are fabricated from structural steel can be erected speedily. This leads to reduced construction time that is often one of the main criteria of the industries during project planning. The short construction time can lead to savings in site preliminaries, reduced project costs and ultimately, improved ROI.

Stainless steel plays a huge role in improving the productivity of construction because of shop fabrication. It enables maintenance of tight construction tolerances. Structural Steel serves as a shop based technology enhancement, thereby offering significant productivity enhancement in construction.

Welding

Welding is one of the most important parts of the metal fabrication process. With the application of the right welding techniques, the strength of structural steel can be enhanced. This makes steel a perfect material for use in high-pressure applications such as columns and I-beams of commercial buildings.

Affordability

Apart from the attributes of strength and reliability that structural steel encompasses, clients also prefer structural steel because it’s cheap compared to other raw materials. Add to this, even the overall cost of the structural steel fabrication process is cost-effective. Its lightweight also contributes to reduced shipping cost. With higher cost-savings, usage of steel offers a higher probability of improved ROI to businesses than other building materials.

Environmentally Safe

As more and more businesses are now inclined towards ‘going green’, steel has gained more popularity among businesses thanks to its sustainable and flexible nature. Steel can be used over and over without compromising on quality. Steel has limited carbon content and is recyclable. Over the years, the process of producing stainless steel in Singapore has become environmentally safe with an increased focus on higher recycle rate and reduction of waste.

With the increased use of steel for structural frames and flooring, more forests can be preserved. It is also effective in blocking out environmental pollutants, resulting in a healthier workplace or commercial space. Modern-day steel plants are designed in a manner that reduces greenhouse gas emissions and is energy-efficient. Even the water used during the manufacturing process of steel is recycled.

For more information on structural stainless steel fabrication in Singapore, get in touch with us at www.fmbtne.com.sg

We are Structural Steel Fabricators, offering metal works and stainless steel fabrication services to industries in Singapore.