Whenever a high-density heat source, like a laser, applied to the surface of a metal workpiece, it is distorted. Now, being able to predict this distortion allows you to use the laser or high-density heat source, and direct it in a specific manner in order to shape and form the metal without the need using any stamping dies or another tooling. In the past, this not actually a feasible option as it required a lot of manual labor as well as skilled operators to perform the complex operation. But now that developments in neural networks and simulation software have advanced, it is possible to predict and determine the feasibility of such a process in the manufacturing workspace.

How it works

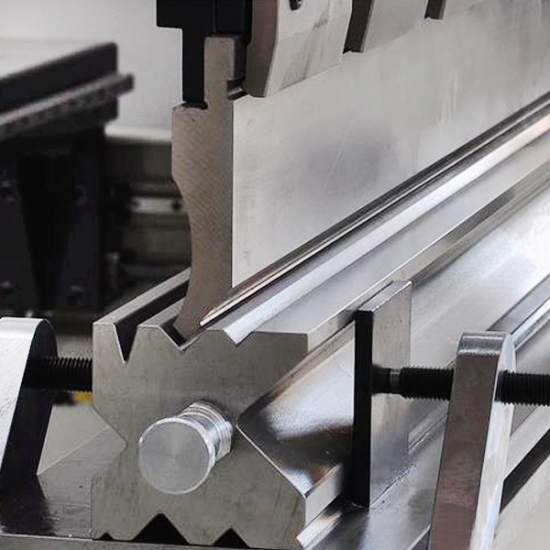

A laser beam is shot down on a specific part of the metal work-piece. Due to its metallic properties, that part of the metal surface will have to expand. However, due to the presence of the cooler metal surrounding it the metal cannot expand to its sides and thus has to extend outwards, away from the surface. Once that portion that has been deformed cools, the stress from shrinking permanently deforms it. This process is then repeated across the surface following a predetermined design specification in order to create the shape required by the manufacturer.

This process has been done before in the industry, however, only in necessary edge cases like forming the large and heavy steel plates for this and also for straightening out steel beams. This technique has also been used to remove the distortion produced from welds during fabrication. The process has been used sparingly due to the complexity behind it and the extensive man-hours required to execute a job properly.

Making it better

The FLAIR project has revolutionized laser thermal forming and made it feasible for more widespread applications. The project is very smart in the sense that it uses DPSs (high-speed digital signal processors) for controlling the intelligence behind it. Using these, it is able to convert computer-aided design models into parts with limited human intervention. In essence, the project works by processing the 3D model and then the neural network determines how the laser should go about forming the actual part. This removes the need for human expertise and intensive labor to work things out. Some of the parts made from this process are either too difficult or almost impossible to create using standard metal bending techniques.

Visualizing it

When you add in some graphics to the whole project, you are able to accurately monitor and track the whole process. The neural network is smart enough to not only process the required motion for the laser machinery but also the real-time properties of the metal and the changes it goes through due to the contraction and expansion during the forming process.

Conclusion

Being able to predict and automate processes like this can be expanded into other manufacturing processes in the metal fabrication industry, like laser cutting and metal rolling and could help stainless steel fabrication, aluminium fabrication, and steel fabrication thrive.