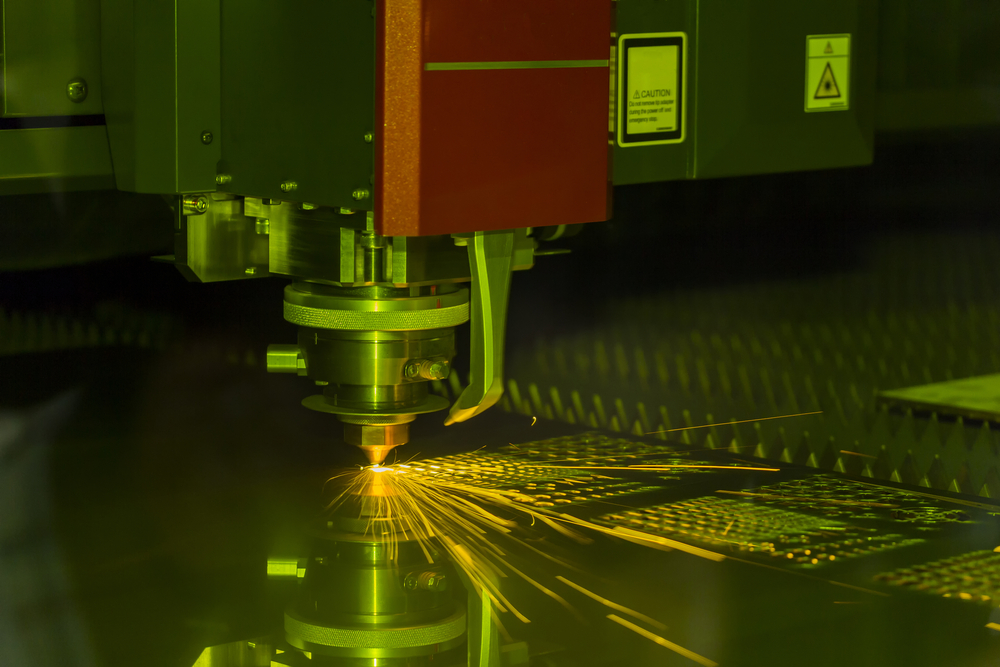

As the metal fabrication industry evolved in the past couple of decades, numerous changes and developments have occurred in metal bending and metal rolling. These changes have been making all processes in stainless steel fabrication, aluminium fabrication and steel fabrication faster and more efficient. And now, the industry has taken another step forward by slowly replacing CO2 lasers with fiber lasers for laser cutting. As with all the other changes, this one brings its own improvements. These faster cutting machines come with their own automatic storage and retrieval towers which allows it to take advantage of its peak cutting capacity. However, understanding and using this newer equipment at maximum efficiency is no easy task.

Teamwork

No matter how advanced technology becomes, solving some of the most complicated problems on the shop floor requires the collective brainpower of experienced individuals. In order to drive a machine with the operational complexity of the new laser cutter at maximum efficiency, a team with the combination of various expertise will be necessary. Otherwise, the performance of the machine will not be up to the mark, and advancing with it will become a challenge. Moreover, your investment in the machine will backfire.

Once the machine arrives, it is up to the management and the production teams to have a proper understanding on how the fiber laser works, what kind of impact it will have on the overall productivity of the shop and what scale of output the production team can expect from the machine. All of these are important as it allows to prepare for future challenges that come along the way.

Testing

In order to be properly prepared for the arrival of the machine that will inherently boost the production capacity of your shop, you need to run some tests and keep some important changes in mind. For example, in the event that the laser boosts your current capacity tenfold, you need to document how your current shop operates at ten times its top capacity before the laser even arrives. This will allow you to find issues either in the backend or front end. Moreover, faster equipment might encourage some workers to try to work faster while ignoring some safety practices. Therefore, safety is also a major concern. Documenting and then figuring out solutions to these problems before the new machine even arrives is crucial in ensuring the most of the machine.

Outside Help Might Be Necessary

It is not always possible for your team to know about every feature of the new machine, therefore investing in outside expertise which will help your team and therefore in production will be very beneficial in the long run.

Reporting and Tracking

Tracking the machine throughout its production lifetime even after it has met its goals and achieved success can come in handy. Quantifying each step in the process will allow the team to achieve one benchmark and then plan for another. Moreover, given the state of progress in the industry, the fiber laser cutter might have to meet a competitor, and in that event, knowing which stages of the process can be improved and being able to compare if the new investment is worth it or not comes down to proper documentation.